Optimal Gilts

The housing of gilts during the growth period is important as this will (among other factors) form the basis of gilt quality, and will set a prime base for high lifetime productivity. Attention to detail starts in the farrowing unit where the focus must be optimising growth conditions in an ideal environment.

|

|

Sow performance and longevity are largely dependent on the surroundings and growth conditions of the young gilt, which is why the focus should be to reach the ideal body condition at the time of mating in the second or third oestrus.

| Goal | Recommendation |

|---|---|

| Weight | 150–165 kg |

| The thickness of backfat | 13-15 mm |

| Daily growth, from 30 kg to mating | 900 g/day |

| Age at mating | 210–230 days |

Supply of feed and water during the growth period

Supply of feed and water during the growth period is amongst the factors with the greatest benefit on the gilts design at the time of first insemination. Both supply of feed, feed quality and principles revolving feeding. The most important thing to keep in mind is that gilts are to be fed as gilts and not finishers.

|

|

Feed and feeding are the foundation for gilts’ growth, conformation and general health. Gilts’ feed must take into account their actual needs with a special focus on leg and bone strength, whilst also ensuring their growth rate is not too fast.

FEEDING IN THE CONTROLLED ENVIRONMENT SECTION

Focus on gilts’ feed needs to start in the weaning section, even if there are no major differences between gilts and remaining piglets during this period. Feeding in the weaning section must support and optimise growth throughout the growth period:

| Age, days | Age, weeks | Weight, Kg | Average daily growth (g/day) |

|---|---|---|---|

| 28 | 4 | 7 | 250 |

| 56 | 8 | 18 | 430 |

| 70 | 10 | 27 | 430 |

| 84 | 12 | 35 | 500 |

| 112 | 16 | 60 | 500 |

| 140 | 20 | 88 | 500 |

| 168 | 24 | 116 | 570 |

| 196 | 28 | 140 | 615 |

| 224 | 32 | 163 | 640 |

| 84-245 | 10-32 | – | 900 |

At weaning, intensify the focus during the first 5–7 days after weaning.

|

|

The feed must be optimised to meet the nutrient demands for the best productivity. Consider the animal’s physiology and, at the same time, focus on minimising post-weaning diarrhoea by using simple but effective feed mixes.

| Starter compound, 4-6 weeks, (6-15 kg) | End compound, 6-10 weeks, (15-30 kg) | |

|---|---|---|

| Energy density per kg feed | 14.0 MJ ME/kg, 10.3 MJ NE/kg, 1.16 FUgp/kg | 13.6 MJ ME/kg, 10.0 MJ ME/kg, 1.12 FUgp/kg |

| Std. digestible lysine, g/kg | 12.8 | 12.9 |

| Minimum std. dig. crude protein, g/kg | 162 | 160 |

| Maximum std. dig. crude protein, max g/kg | 172 | 169 |

| Digestible phosphorus, g/kg | 3.7 | 3.7 |

| Calcium, 60-100%, phytase, g/kg | 8.7 | 9.0 |

|

|

|

It is advisable to use a liquid starter mix the first 5–7 days after weaning.

- Mix in a ratio of five parts water, one part milk and two parts starter feed.

- Allow one litre of liquid starter mix per ten pigs.

- The pigs should have emptied the trough after 20 to 30 minutes- if not, consider feeding slightly less until they begin to eat more. Ensure any leftover feed is cleaned out of the trough before the next feeding

- Feed the liquid starter mix to the pigs at least four times a day, preferably more, as multiple feedings are better.

When feeding the liquid starter mix, be particularly aware of hygiene. It is advisable to clean troughs after feeding. It is a good idea to leave a small amount of water in troughs as an additional water supply.

After one week in the weaning section, the transition to dry feed should be completed. Feed restrictively for the first 12 days, after which they can be fed ad libitum.

WATER FOR WEANED PIGS

Water is essential in this period to maintain growth, which is why there must be unrestricted access to clean drinking water. It is advisable to have at least two water valves per pen, preferably more. The water valves should be placed as close to feed dispensers as possible to optimise their use and increase feed intake. It is recommended for water valves to release between 0.5 to 1.0 litre/min. Be aware of the water pressure. The water valves should be able to maintain the recommended flow rate when 20 % of the drinkers are in use.

|

|

|

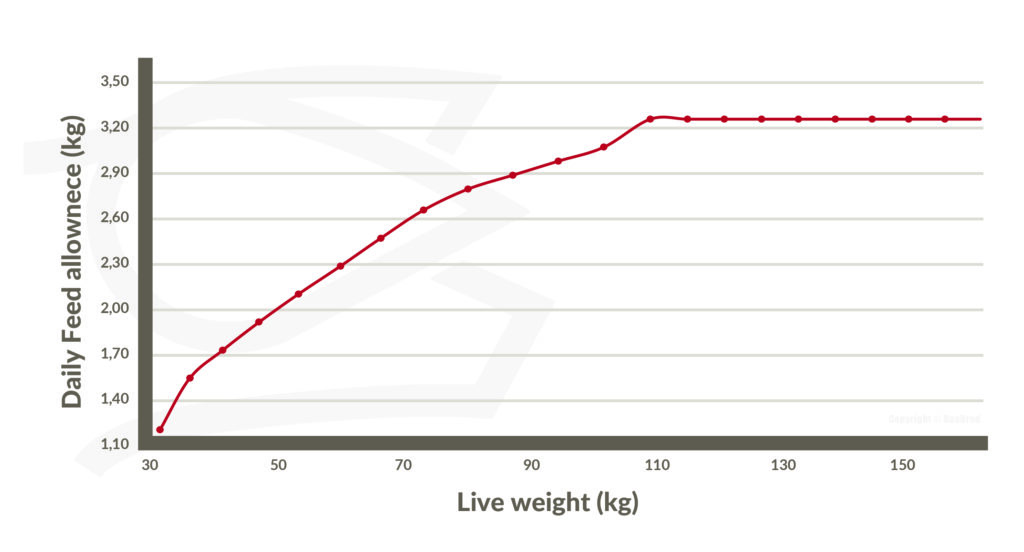

Feed curves during the growth period

Phase feeding of DanBred gilts will secure good longevity and lifetime productivity. Feeding DanBred gilts according to one of the following feeding scenarios will assure optimised performance and fitness of the gilts.

| Scenario 1 | Gilts 30-60 kg | Gilts 60-110 kg | Gilts >110 kg |

|---|---|---|---|

| Scenario 2 | Gilts 30-85 kg | Gilts 85-110 kg | Gilts >110 kg |

Restricted growth among the gilts is important. Maintaining a growth rate of around 900 g/day from 30 kg up to 150 kg will ensure adequate depositing of fat and thus improve oestrus and increase litter sizes. In addition, the recommended growth rate will improve the gilt’s leg strength as it allows bones to develop more slowly, thereby optimising the depositing of minerals in bones.

From 30 kg to 60 (85) kg, feed the gilts according to approximate appetite, after which restricted feeding is recommended. Restricted feeding makes it easy to control the daily growth rate of the gilts. The table below shows the recommended feed composition for restrictive phase feeding.

| Restricted phase feeding | 30-60(85) kg | 60-110 kg | 85-110 kg | > 110 kg |

|---|---|---|---|---|

| Energy density per kg feed | 13.0 MJ ME/kg, 9.8 MJ NE/kg, 1.07 FUgp/kg | 12.8 MJ ME/kg, 9.7 MJ NE/kg, 1.05 FUgp/kg |

12.7 MJ ME/kg, 9.6 MJ NE/kg, 1.04 FUgp/kg | 12.5 MJ ME/kg, 9.4 MJ NE/kg, 1.02 FUgp/kg |

| SID lysine per kg feed (g) | 8.2 | 6.3 | 5.2 | 4.1 |

| Total lysine per kg feed (g) | 9.4 | 7.2 | 6.0 | 4.7 |

| Min. SID crude protein per kg (g) | 126 | 105 | 94 | 82 |

| Phosphorous per kg (g) | 5.6 | 4.4 | 4.4 | 3.9 |

| Digestible phosphorus per kg (g) | 3.2 | 2.4 | 2.4 | 2.0 |

| Calcium per kg (g) | 8.6 | 7.4 | 7.3 | 7.3 |

² Based on the usage of 100% phytase

For a higher amount of fat deposit, it can be advisable to feed a special “body condition” compound which is given on top of the daily ration. This feed mix can be made up of 2% fat, half barley and half wheat plus vitamins and minerals. Generally speaking, adding fat to the compound feed will help to increase the deposit of fat in the gilts an added bonus is that the fat can help reduce dust issues in the stables.

The general feeding strategy should be followed up with quality feed components and focus on the health and development of gilts.

GASTRIC HEALTH

Optimal gastric health is essential for optimising the efficiency and longevity of very productive sows. This starts during the growth period, by focusing on the choice of raw materials and feed-composition quality.

Feed compounds with high fibre content have a positive effect on gastric health and are an important parameter in preventing stomach ulcers and producing uniform gilts. Fibre should always be added to feed compounds for gilts as well as sows. Uniformity is one of the goals in gilt production, as this helps to ensure uniform sows in the production facility.

| Ad libitum | Restrictive | |

|---|---|---|

| Admixture percentage | 3,5 % | 12-15 % |

Both the volume and the quality of the fibre source are crucial, as this will reduce the animals’ feed intake and limit their growth, thereby producing more uniform gilts.

Housing of gilts

Housing during the growth period is crucial for the quality of gilts as breeding animals in the herds. Housing conditions are not only important for gilt health and well-being, but also for their conformation and productivity.

|

|

PEN SPACES FOR GILTS

During the growth period, gilts can either be housed in a separate gilt section or in selected pens in existing housing units. Regardless, it is always advisable to keep – as well as feed – gilts separately from sows wherever possible. In addition, make sure to place gilts in an area of the housing unit that is monitored several times a day.

|

|

|

Calculate the number of pen spaces for gilts on the basis of the expected replacement rate per year. It is advisable to base the replacement rate on the current needs of the individual herd and, at the same time, focus on maximising efficiency in the gilt production combined with a focus on maintaining as high a breeding value as possible. In other words, the calculations should consider both the common causes of culling in the herd and, not least, culling based on low index levels.

|

|

|

Pen layout

The layout of pens for gilts must consider the quality of the gilts and their natural behaviour. Promoting natural behaviour will promote positive behaviour among gilts in general, which will make them easier to handle.

|

|

Pens for gilts should have two-thirds of solid or drained concrete floors in the lying area and one-third of slats, pen dividers should have bars in the slatted floor area.

In order to provide water at all times, the pen should be equipped with drinking bowls or troughs with vacuum valves in the solid-floor area, as well as drinking nipples in the slatted-floor area.

|

|

|

Make sure the walls separating the pens are roughly one metre tall to prevent gilts from jumping into a neighbouring pen or otherwise getting injured in the attempt.

Climate

In addition to the pen layout, the ambient climate and environment must also be taken into account in the gilt section. Ambient temperature affects gilt growth via food intake and health, which is why it is crucial to focus on maintaining an ideal temperature at all times.

The focus of the weaning section must be on both the ambient temperature and floor heating, outside as well as underneath the cover in the pen.

| Weight (kg) | Temperature under covering (°C) | Floor temperature under covering (°C) | Ambient temperature (°C) |

|---|---|---|---|

| 5.5 | 31-32 | 32 | 25-26 |

| 6.0 | 30-31 | 32 | 24 |

| 7.0 | 29-30 | 32 | 24 |

| 8.5 | 28-29 | 32 | 23 |

| 11.0 | 27-28 | 32 | 22 |

| 14.0 | 26-27 | 32 | 21 |

In the gilt unit, ambient temperature is the primary consideration, while the floor heating can be phased out.

| Weight, kg | Temperature, C° | |

|---|---|---|

| Gilts | 15 | 22-24 |

| 25-40 | 18-22 | |

| 40-100 | 15-20 |

* If not using an All-in-All-out batch strategy, but new gilts are introduced to the unit regularly, the diffused ventilation must be adjusted accordingly.

All-in-All-out batch strategy is rarely practised in the gilt units. When regularly adding new animals to the unit, it is difficult to provide a general recommendation that solely applies to ambient temperature, as the optimal temperature is dependent on the size of the gilt. Therefore, it should always be possible to add heat individually to the pens. Pens for pigs up to 30 kg should be established with dual climate, where it is possible to cover part of the pen while the gilts are small. Underfloor heating with an option for bedding in the lying area is also recommended while the gilts are small.

|

|

|

It must be possible for big gilts to cool themselves down, therefore it is highly recommended to install a sprinkler/showering system for all gilts above 20 kg if this is not already installed due to law regulations. This can be combined with a high-pressure cooling system as an additional option for temperature adjustment in hot periods.

|

|

Sorting and stocking density

For the production of breeding animals, there should be a focus on the correct sorting of animals in all housing sections- this begins at weaning.

Breeding animals should be sorted according to their race and gender once they reach a certain size. Grouping by race is crucial as purebreds and F1 hybrids require a little extra attention.

It is recommended to house gilts in separate pens, and otherwise not mix with other animal groups in order to provide them with the attention that they need.

|

|

|

At weaning, the gilts are sorted at around 30 kg and the gilts should be divided into small groups.

It is recommended to keep gilts in stable groups of breeding animals only. Keep a maximum of 6–10 females per pen. These stable groups should be maintained until the first oestrus is observed. Afterwards, it is advisable to move the animals to the mating unit.

| Weight, kg | Recommended area, m² |

|---|---|

| < 10 | 0.15 |

| 10-20 | 0.20 |

| 20-30 | 0.30 |

| 30-50 | 0.40 |

| 50-85 | 0.75 – 1,00 |

| 85-110 | 0.75 – 1,00 |

| > 110 | 1.50 – 1,90 |

* The recommended area does not include the floor space under troughs.

The floor-space requirement is a guideline, the primary goal should be to provide enough space for all gilts to be able to eat at the same time regardless of their size. If floor feeding is used for the gilts, it can be beneficial to increase the area per animal to ensure sufficient space for feeding all gilts and try to reduce aggression and/or competition between animals.