Production Facilities

The weaner and finisher units are where the pigs stay until ready for slaughter. The goal for these production facilities is to maintain healthy pigs in a balanced production flow. Focus on optimising the conditions of the housing environment is important for both animal welfare, biosecurity and in the end profitability.

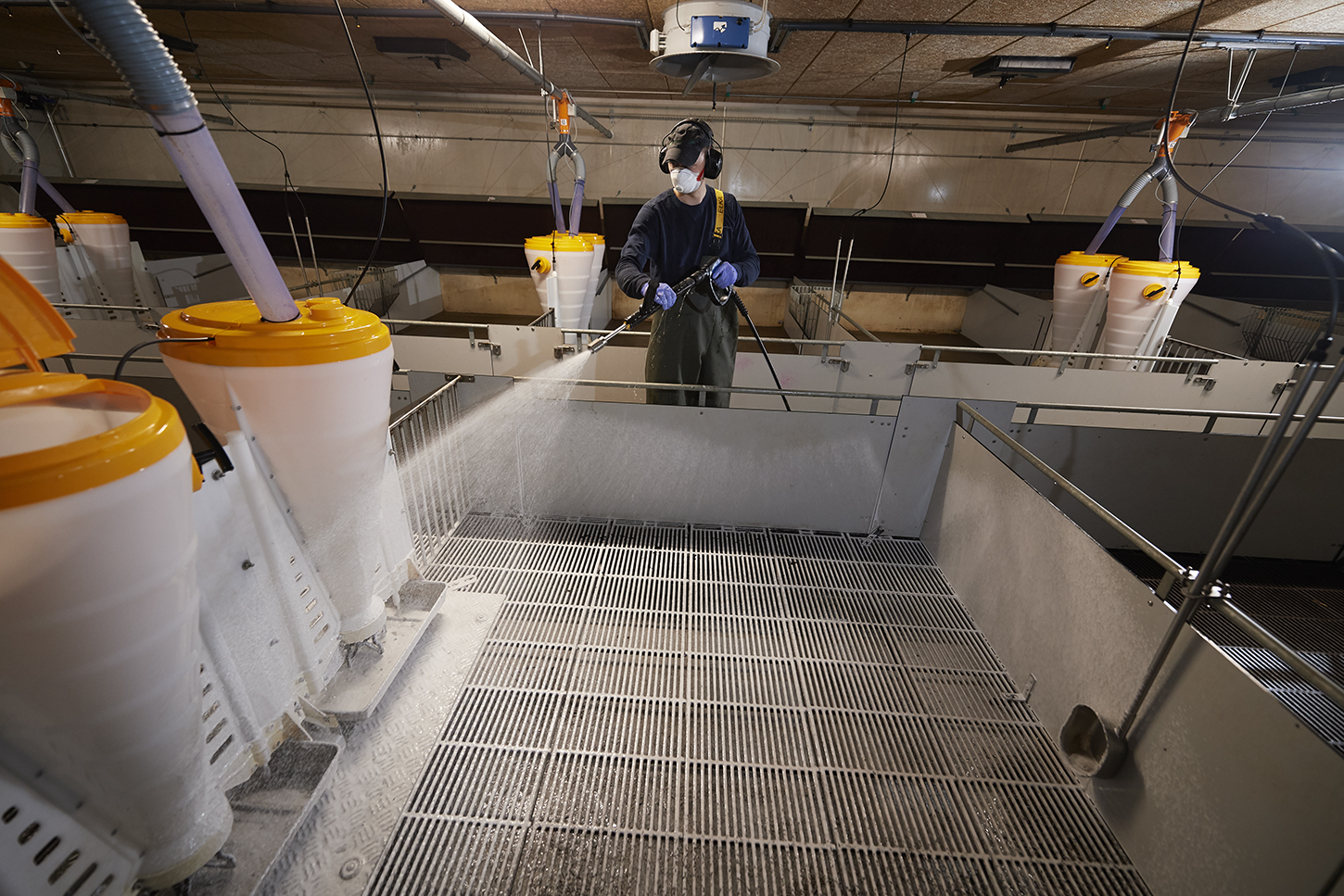

Preparation for new pigs – cleaning procedure

Before the weaned pigs, the finisher unit has been washed, disinfected and dried out. This is essential for animal health and it reduces the risk of diseases developing and spreading.

- Make sure the slurry pits are empty.

- Soak all surfaces, including walls, floors and fixed equipment. Let them soak for 12 to 24 hours.

- High-pressure wash all surfaces with clean water, making sure everything is visibly clean.

- Wash all surfaces with soap on the same day as high-pressure washing with water.

- Rinse everything with low-pressure water on the same day as washing it with soap.

- Disinfect all surfaces on the same day as the rinse.

- All surfaces and areas must be dry before the new animals arrive. The ambient temperature should be at least 22°C when they arrive, why it might be necessary to add heat to properly dry out everything.

- Now the unit is ready for the new pigs to arrive.

- To ease the move into the unit, move the pigs one pen at a time.

Disinfection of the water system

Water for pigs should have the same quality as human drinking water – quality measures can be found here.

To ensure a consistently high quality of the water with the pigs it is extremely important to disinfect the water system to remove any biofilm from the water pipes, as biofilm could be teeming with infectious bacteria.

- Empty and rinse the water system twice with an approved disinfectant and at least once with clean water.

- Carry out the first rinse after washing the surface of the water nipples or drinkers.

- Complete the second rinse the day before the animals arrive – and not before.

- Let the cleaning product soak in for about 5 hours.

- Make sure the water system is rinsed with clean water at least once before the animals arrive.

|

|

|

Introducing pigs to the finisher unit

- Sort the pig by size at weaning.

- Pay extra attention to the smaller pigs.

- Ensure that the smallest pigs are not placed in end pens, under ventilation or in pens with temperature or humidity sensors.

- Use a “two-climate” pen where a part of the pen can be partly covered – make sure to lower the cover to create a warm environment for the newly weaned pigs.

- If possible use bedding material under the cover, placing a board across the pen can help ensure that bedding material stays in the lying area.

- A heating lamp, a hygienic plastic curtain or a temporary paper curtain can be added to keep the temperature up underneath the cover.

|

|

Pen design and Stocking density

Optimising pen design to ensure sufficient space for each pig is important for both high health, optimum growth and animal welfare.

When managing a professional high-performance pig production, considerations of production facilities are very important, choosing the correct setup will have an instant effect on disease pressure among the pigs as well as an effect on growth performance and general animal welfare. Factors have a direct impact on production results and can lead to economic success when handled with the proper attention to detail.

Every setup is different and so are the rules in force. Any local legislation should of course always be respected.

Stocking density

Pen size and thereby ultimately the stocking density should always be optimised according to the biggest pigs in the pen. If the production facility is meant to hold the pigs in the same pen through the full growth period, the space requirement must consequently be designed to accommodate the needs of the pigs when they are at their biggest.

Meeting the space requirements of the pigs at all weight stages is of significant importance for ensuring maximal daily growth and thereby animals utilizing their full genetic potential.

The below stated is the recommended minimum requirements per pig, local legislation on space requirements should of course always be respected.

| Average weight per pig, kg | Minimum of space per pig, m² |

|---|---|

| Weaning – 10 kg | 0.15 m2 |

| 10-20 kg | 0.20 m2 |

| 20-30 kg | 0.30 m2 |

| 30-50 kg | 0.40 m2 |

| 50-85 kg | 0.55 m2 |

| 85-110 kg | 0.65 m2 |

| Above 110 kg | 1.00 m2 |

Space per pig is only the floor area inside the pen which is available to the animals. Troughs, feeders, pen walls etc. are not included.

Pen design

The pen design and especially the ratio between the length and width of the pen has shown to be of importance for the behaviour and welfare of the pigs, hence the optimal growth of the pigs.

Dimensions

Proper pen dimensions will encourage the correct use of the pen area, with regard to rest areas and dunging areas. Furthermore, correct pen design can help ensure an easy and simple everyday inspection of animals.

The recommendation is to aim for a pen ratio where width versus length is between 1:2 and 2:3.

As example:

- ) If a pen has a with 2.3 meters the 1:2 ratio will give a pen length equal to 2 x 2.3 = 4.6 meters.

- ) The same pen with a 2:3 ratio will have a pen length equal to (2.3/2) x 3 = 3.45 meters.

The optimal pen length for this setup will therefore be between 3.45 and 4.60 meters to accommodate correct pen functionality in regard to pig inspection, the use of the resting area as well as the use of the dunging area.

Pen separations

The design of the partitions between pens can also influence how the pigs use the pen. It is advised to design partitions to both accommodate the natural behaviour of the pigs as well as being easy to maintain and properly clean.

|

|

Installing partly open partitions fully or partly closed in the lying area will encourage the use of the lying area. The partly open partition where the lower 60 cm of the wall is closed while the upper 20-40 cm is open with horizontal bars can ensure air quality as it allows the air to flow easier than the fully closed walls.

In the dunging area, every second pen partition should be fully open with vertical bars. This will encourage correct dunging behaviour keeping the lying area dry and clean.

Floor design

The design of the floors can have an impact on air quality and the working environment, why local legislation may apply to the layout which should be respected.

Pens are designed to support the welfare and growth of the pigs, and must therefore accommodate the 3 main needs of the pigs: resting, feeding and dunging.

The recommendation is to design the floor areas according to the function of the individual pen areas.

- Minimum 30 % of the pen is a solid concrete floor.

- This functions as a resting area and should be placed at the far end of the pen.

- The solid floor should have a slope of 3% towards a drained area.

- Floor heating is recommended.

- Approx. 20% of the pen area should be drained floor based on concrete slats.

- Drained floors have an open area at a maximum of 10% of the total area.

- This area supports a dry and clean laying area.

- 50% of the pen should be a regular slatted floor in cast iron or concrete.

- This area is where the pigs will defecate.

- Feeders, as well as water valves, can also be placed partly in this area to ensure pen hygiene.

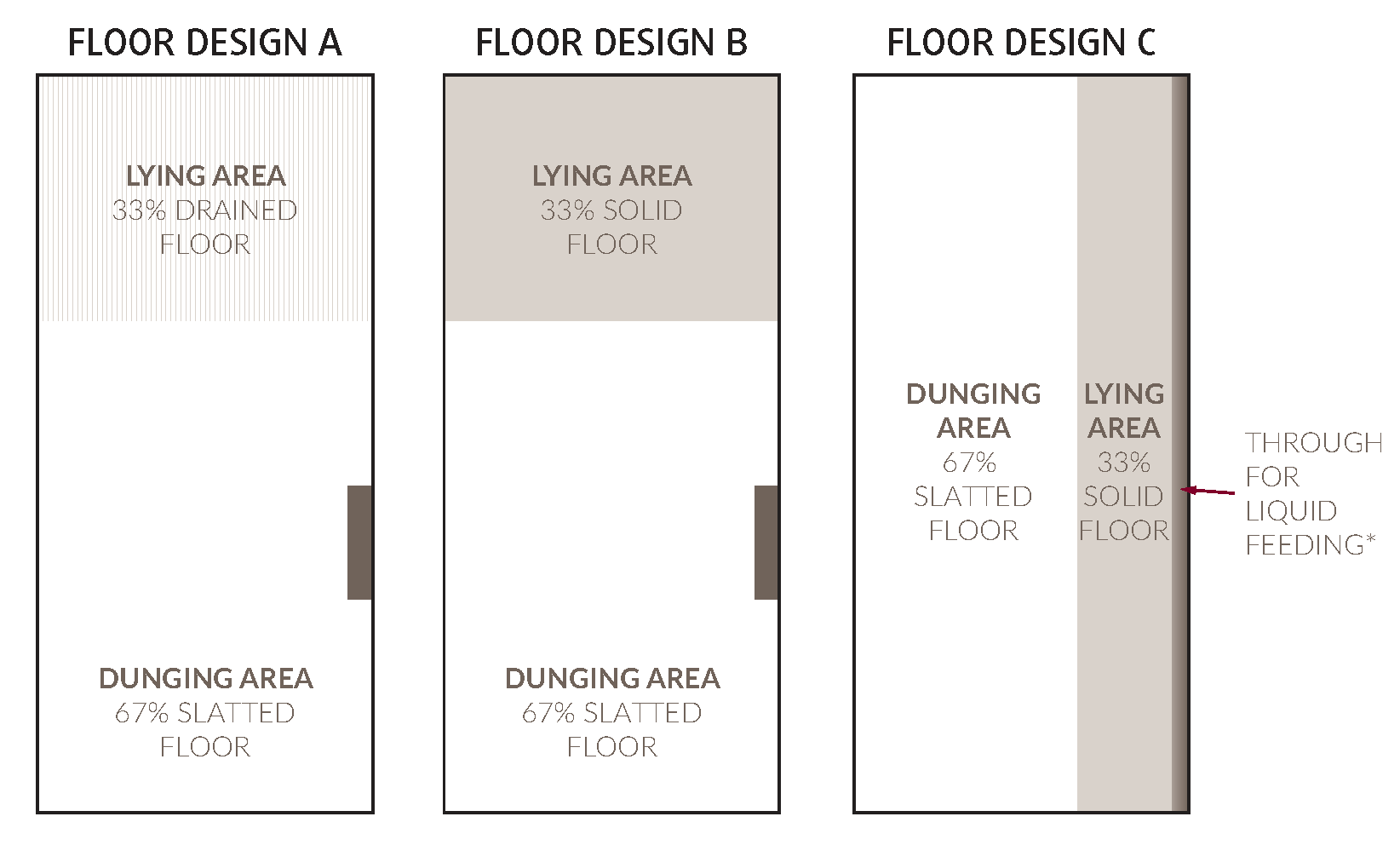

Useful alternatives to the 30/20/50 design are described in the figure below.

A) A drained floor in the lying area.

Approximately 33% of the floor is drained floor, consisting of the concrete slatted floor where the open area has a maximum of 10% of the total pen area.

An example: A slit opening of 18 mm, giving a closed slit of 180 mm or above.

The remaining part of the pen is a regular slatted floor.

B) A solid floor in the lying area.

Approximately 33% of the floor is a solid concrete floor, with a 3% slope towards the slatted floor.

The concrete floor is placed at the far end of the pen.

The remaining part of the pen has a slatted floor.

C) Solid floor placed along the length of the pen

Approximately 33% of the floor is solid concrete floor placed along the length of the pen together with a full-length trough for liquid feeding.

The concrete floor is with a slope of 3%. The concrete floor is placed along the length of the trough.

The remaining part of the pen has a slatted floor.

*When using a liquid feeding system with long troughs the pen layout must accommodate that all pigs can eat at the same time. Ensure that each pig has between 30-35 cm trough space per animal from a weight of 30 kg until slaughter.

Drinkers

Effective water management contributes to a good foundation for a healthy pig. Focus on sufficient water supply, water quality is of high importance.

The choice of drinkers often depends on housing and pen design. An important factor to consider is ensuring that water is available for all pigs in the amount needed.

Below are recommendations for drinking bowls and drinking nipples in the weaner, grower and finisher sections. For recommendations on water quality, and amounts click here.

Correct water flow throughout the production facility is important. The water supply should be able to maintain reliable flow rates for all drinkers even when the main part of the drinkers is in use.

|

|

| Type of drinker | Drinking bowl | Drinking nipple |

|---|---|---|

| Water flow piglets | Minimum 1 l/min. | Maximum 0.5 l/min. |

| Water flow weaners | Minimum 1 l/min. | 0.5 – 0.8 l/min. |

| Water flow growers and finishers | Minimum 1 l/min. | 0.5 – 1.2 l/min. |

| Drinkers per piglet and weaners | 20-50 pigs per bowl | 10 pigs per nipple |

| Drinkers per grower and finishers | 15-30 pigs/bowl | 10 pigs per nipple |

| Comments | Minimum 2 bowls per pen or an alternative water option | Minimum 2 nipples per pen. |

Due to growth, health and welfare, a backup water supply should always be available for the pigs in case of defects.

Drinkers should always be mounted to accommodate the smallest pig in the pen with full access, at the same time the drinkers must be placed strategically concerning both hygiene and access. Drinking bowls should for example never be placed in a corner as this increases the risk of pigs soiling the drinkers.

Additional pen equipment

To support animal behaviour and welfare, it is recommended to include some sort of rooting or Enrichment materials or regular pig toys in each pen. This can activate the pigs and prevent unvented behaviour such as tail-biting, flank chewing, and ear-sucking/-biting. Any local legislation should of course always be respected.

Rooting materials and pig toys come in many different shapes and sizes a few examples are:

- Wooden sticks can be placed in a bracket on the pen partition.

- Sisal ropes hung from the ceiling into the pens.

- Paper sacks and other non-toxic disposable paper or cardboard materials can be thrown into the pens.

- Straw – be aware that straw can create issues with moving out the manure if pens have a slatted floor.

Climate

The impact of ambient temperature on swine health should never be underestimated. Correct room temperature promotes ideal growth, high feed utilisation and good health.

Observing pigs lying behaviour is can be used as an indicator for temperature adjustments.

Pigs within comfort temperature will mainly lie next to each other in the dedicated lying area.

Pigs kept in temperatures below their comfort zone will often huddle together and lie almost on top of each other.

Pigs kept above their comfort temperature will lie on the side away from other pigs and will often lie in the dunging area. More than one pig lying in the dunging area can be an indicator that ambient temperature needs some attention.

Temperature strategy

Climate, housing facilities and ventilation design are all important factors to consider when deciding on a temperature strategy.

As described observing the pigs’ lying behaviour and their use of the pens can give a clear indication of whether the temperature is too low or too high in the pens.

For weaners, it is advised to use two-climate pens, with a solid floor in the lying area.

|

|

A “two-climate” pen with a removable cover can ensure that the temperature needs of the pigs can be adapted as they grow. If placed in a colder climate it can be an advantage to add curtains or plates which can partly cover the entrance of the covered area for optimising temperature while the pigs are small.

The cover should of course never stand in the way of proper air exchange or cause an unnecessarily hot environment for the pigs.

| Weight | 5.5 kg | 6 kg | 7 kg | 8.5 kg | 11 kg | 15 kg | 18 kg | 25 kg | 30 kg |

|---|---|---|---|---|---|---|---|---|---|

| Ambient temperature beneath the cover, ° C | 31-32 | 30-31 | 29-30 | 28-29 | 27-28 | 26-27 | 25-26 | 22-23 | 21-22 |

| Floor temperature beneath the cover, ° C | 32 | 32 | 32 | 32 | 32 | off | off | off | off |

| Set temp. room*, ° C | 25-26 | 24 | 24 | 23 | 22 | 21 | 20 | 19 | 18 |

| Set humidity room**, % | 60 | 61 | 61 | 62 | 63 | 64 | 70 | 71 | 72 |

| * The room temperature must be adjusted to achieve the desired temperature under the cover.

** Note. The less humidity required, the higher the heat consumption in the facility. |

|||||||||

Temperature sensors

Installing temperature sensors will help adjust ventilation and airflow in the housing units.

- Place the indoor sensor in a representative spot in the facility, preferably in the middle of the pen 1.2 meters above the pigs.

- The temperature sensor should always be above the pigs (not an empty pen).

- Ensure that the temperature sensor measures the temperature correctly. If compromised by ventilation draught or cold airflow a plastic cover or similar device can be introduced.

- Place the outdoor sensor in a way that it is not compromised by solar influence.

- Avoid placing the smallest pigs in pens with humidity or temperature sensors.

Coping with high ambient temperatures

For health and welfare purposes it is advised to establish an efficient practice for coping with high ambient temperatures. In addition to good ventilation without draught, water sprinklers or foggers can be used to help the pigs stay cool and comfortable.

Pay extra attention to pen hygiene and ensure increased animal supervision during the hotter periods, as the pigs might start using lying areas with solid floors for dunging and slatted areas for lying if ambient temperatures are above the pigs’ comfort zone.

Sprinkling the animals work through cooling the pigs and not through cooling the air in the facility, why the proper application will increase the efficiency.

Ensure that the pen has water spraying nozzles mounted above the dunging areas. Adjust the timers to regularly initiate spraying throughout the day. An example could be to spray for 1-3 minutes every 30 minutes.

Make sure to regularly check that all sprinklers work properly this could be done when washing the sections between batches.

|

|

Air quality

Ensuring air quality will help maintain health, welfare and performance not only for the pigs but also for the people managing the pigs.

The 3 major congratulators for reduced air quality in pig housing are carbon dioxide, ammonia and hydrogen sulphide.

Our recommendations for air quality follow the standards set by CIGR, International Commission of Agricultural and Biosystems Engineering.

| Agent | ppm |

|---|---|

| Carbon dioxide, CO2 | 3,000 |

| Ammonia, NH3 | 20 |

| Hydrogen sulphide, H2S | 0.5 |