Health management and Biosecurity

To maintain consistently high productivity and growth among the pigs it is important to ensure the health status of the pigs.

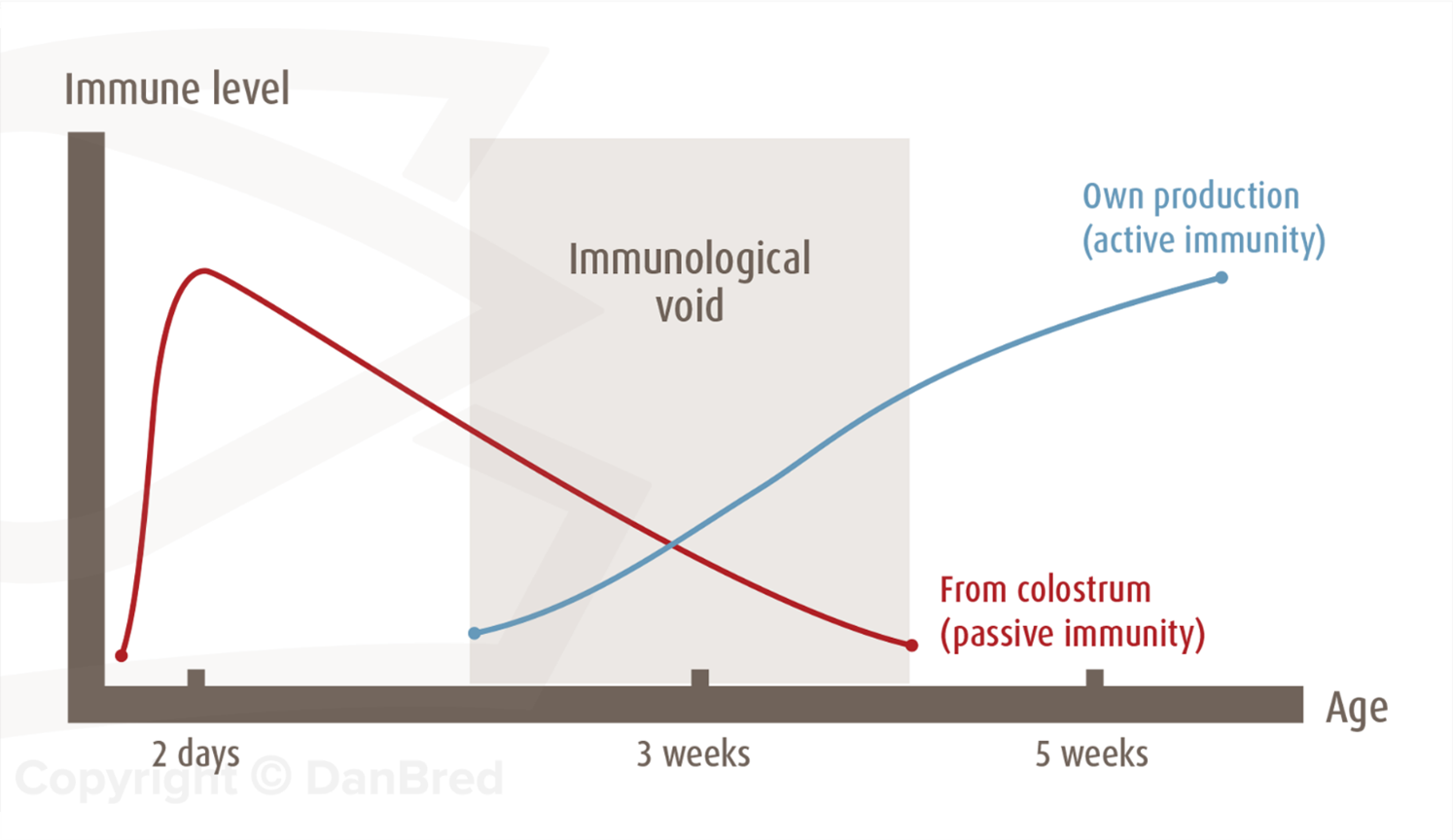

Pigs are generally born without any health complications but also without any antibodies to protect them from pathogens in the surrounding environment. This is why the first suckling of colostrum with the sow is very crucial, as the colostrum contains antibodies that will act as the immune defence until the piglet has developed its own immune system within the first 3-5 weeks of life.

To maintain the high health of the farrowing unit throughout the production, it is recommended to wean pigs in batches into empty, cleaned and disinfected production units. Furthermore, it is highly recommended to use an “All-In–All-Out” (AIAO) production system, that keeps the pigs together in groups from weaning until slaughter, without mixing pigs from different groups.

|

|

If the production system is run systematically with a high level of biosecurity, the pigs should be able to maintain the health status they arrived with from the farrowing unit, regardless of the production system.

It is thought important to initiate a proper health protocol in collaboration with the herds’ veterinarian to ensure the health and well-being of the pigs. Managed correctly this will help utilise the full genetic potential of the pigs without unnecessary use of antibiotics or production losses due to poor health management.

Biosecurity

Any pig production will have some kind of endemic subclinical disorders that are in balance, and if nothing disturbs it will be controlled by natural immunisation among the pigs.

Well-defined biosecurity protocols are the key to maintaining a status quo health-wise and protecting the pigs from unwanted disease outbreaks or zoonosis.

Farm entrance biosecurity

People are among the biggest risk factors when it comes to the introduction of diseases into pig production. Having a clearly defined code of conduct when it comes to entry into the farm, can reduce the risk of people transmitting unwanted pathogens into the herd.

Minimise the number of visitors and keep a logbook where everyone who enters the herd, signs in with the date, name and date for the last visit to a pig herd. Downtime of at least 12 hours between visits in pig herds is recommended.

|

|

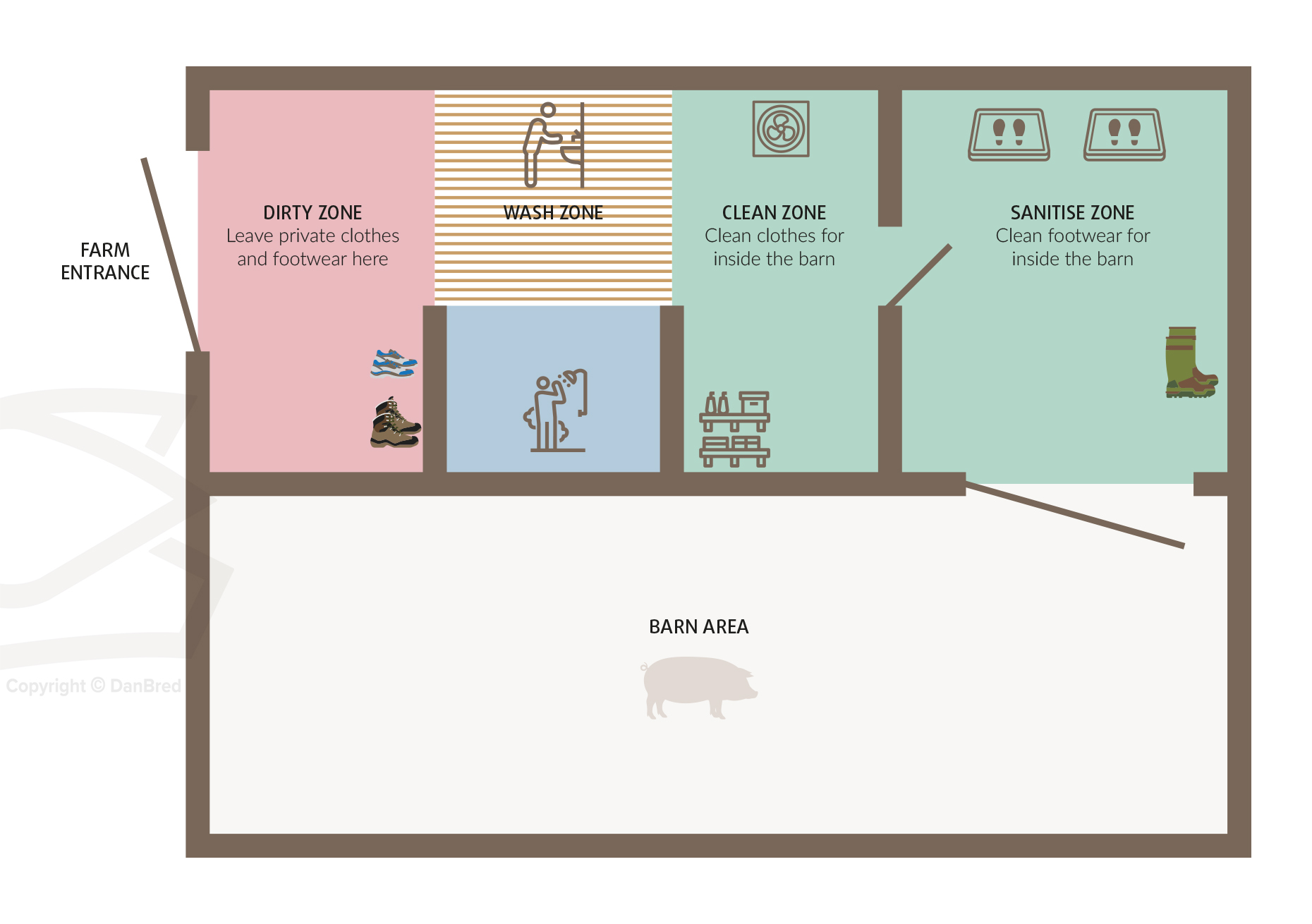

Ensure one clearly defined designated entry room with a dirty zone and a clean zone. Everyone arriving should at minimum change clothes and footwear as well as wash and disinfect hands before entering the premises. “Shower in” can also be practised, if the physical conditions can accommodate this.

The entry room is the key to maintaining constantly high health in the herd, why it is imperative that the entry room is designated for this alone and not used as a storage facility or for any other business.

The entry room should be designed in a way that will promote biosecurity and nudge visitors to follow the rules by instinct.

This includes:

- Keeping a coat rack and a shoe tray for arrival clothes in the dirty zone.

- Placing a “no shoes” grid on the floor leads to the clean zone.

- Ensuring clean clothes and shoes are available for all visitors in the clean zone.

- Locate the sink on the way to the clean zone and ensure soap and paper towels are available.

- Place hand sanitiser in the clean zone preferably just next to the inner entry door.

Watch the video below where pig333.com show does and don’ts when it comes to on-farm entry.

Source: Pig333, Apr 1, 2019: Farm biosecurity #1 – Farm entry. YouTube: https://www.youtube.com/watch?v=NhKJNdtEr84.

On-farm deliveries of feed and equipment

Any delivery of goods to the farm should be done without the arriving trucks, feed or equipment compromising the health and biosecurity of the farm.

Deliveries should arrive at a designated stock delivery area, where it is possible to unload with as little physical contact with the farm as possible. Vehicles and/or goods that enter the farm area, must not be near any other pig farms and should be free of visible dirt. Wapping and/or packaging should to the extent possible be removed and disposed of before the goods enter the herd. Tools and/or equipment that go into the herd should be cleaned and disinfected before entry.

|

|

|

Transport of pigs

Swine transports pose a risk to on-farm health so any arriving swine transports must be empty, thoroughly cleaned, and disinfected before arrival at the perimeter.

Make sure to check and approve that the truck is cleaned according to on-farm standards before it arrives at the loading bay.

|

|

Loading facilities and loading bay

Loading pigs for transport to market can be stressful for both the pigs and the people handling them, why it is important to design the loading facilities as well as the loading bay in a way that will decrease the loading time as well as the need for handler intervention to prevent stress for the animals and people. Furthermore, high biosecurity should always be in focus when loading pigs.

|

|

Make sure to have a designated loading facility and loading bay, that is easy to wash and disinfect between loadings. The loading facilities and loading bay can be divided into an on-farm clean zone and an off-farm dirty zone.

Loading should include enough employees to ensure both clean zone and dirty zone handlers are available. While loading the pigs maintain a one-way motion from the clean zone towards the truck, avoiding any pigs or people that have entered the loading bay to return to the clean zone.

|

|

In a well-designed load-out, the pigs will move easily in the correct direction with minimum intervention. This will minimise cross-over of traffic between the clean and dirty zones and will reduce the risk of contamination from the truck to the farm.

After the loading is done, ensure that the loading facilities and loading bay is cleaned and disinfected before further use.

Watch the video below where pig333.com show the does and don’ts when it comes to loading pigs.

Source: Pig333, Apr 1, 2019: Farm biosecurity #2 – Loading bays.YouTube: https://www.youtube.com/watch?v=pazoTbHyYHU

On-farm pest control

Pests contribute to poor health and welfare for pigs and staff and can cause increased maintenance, veterinary and, feed costs as well as increased feed spoilage and wastage. The constant availability of feed, shelter, and waste available in pig farms provides the ideal environment for pests to proliferate.

Rodents

To decrease the risk of rodents on-farm, make sure to keep the surroundings tidy and avoid vegetation around the buildings. Active control with traps or locally allowed rodenticides is advised. Always consult local experts before initiating pest control initiatives.

Insects

Stinging insects such as flies (stomoxys calcitrans) or mosquitoes can bring bacteria or viruses from nature into farms. This can to some extent be avoided by initiating initiatives that impair the living conditions of the insects. This can be done by regular cleaning and efficient drying out of the premises. Active insect control by physically putting up fly screens, electrocuting lights, and sticky tapes. Chemically control by using approved insecticides approved for on-farm use.