DanBred Nutrient Specifications

These nutrient specifications are a guideline for composing, optimizing, and adjusting feed and feeding levels for DanBred genetics and can facilitate the balance between optimal body condition and reproductive performance as well as minimize an environmental impact from excretions.

The recommendations are based on ongoing trials and results made in association with the Danish Pig Research Centre, SEGES Innovation, combined with on-farm results gained from the collaboration with ADDCON, BIOMIN, VILOMIX Denmark and HAMLET PROTEIN.

Careful attention to feed and feeding levels for DanBred genetics will set a prime starting point on the road to releasing the genetic potential for consistently high lifetime productivity.

For questions on requirements specific to your location please contact DanBreds Technical Service Center for obtaining accurate information.

Technical Service Center

[email protected]

+45 45 4488 1188

Basic nutritional requirements of pigs

The feed must cover the nutritional requirements of the pigs for maintenance, production of meat and milk as well as foetal development. On top of this, feeding should be a part of securing the health and welfare of the pig together with the economy of the producer.

The feed costs in any production system are the largest component of the expenses. Feed conversion and daily gain are some of the decisive factors when considering whether production is cost-effective or not. Therefore, it is crucial to control the feeding strategies, the content of nutrients in the balanced feed, and the feed hygiene in the herd. Also, to ensure the maximum utilization of the genetic potential of the hyper-prolific modern bred.

Nutrient supply

The main factor to consider when designing a nutrition program is the total energy provided by the feed levels of protein, amino acids, carbohydrates, and fat. Carbohydrates provide the body with energy and can be converted into body fat. They can consist of monosaccharides (e.g. glucose), disaccharides (e.g. sucrose and lactose), oligosaccharides (e.g. lupins, soybeans, and peas), and polysaccharides (e.g. cellulose and starch).

Fats provide energy in a more concentrated form than carbohydrates and can also be converted into body fat. Like carbohydrates, fats are compounds of carbon, hydrogen, and oxygen and store most of the animals’ energy reserves. Tallow and vegetable oils are the most common fats added to pig diets- some polyunsaturated fatty acids (e.g. n-3 and n-6 types) are essential for pig growth.

All proteins are compounds of carbon, hydrogen, oxygen, and nitrogen. Proteins are an essential part of cells, where they regulate life processes, provide structures as well as being needed for the body’s growth and repair. Proteins consist of chains of amino acid units, and how the amino acid units are linked gives each protein its characteristic properties.

If producers know the relationship between energy intake and lean muscle growth for pigs of different ages or sizes, they can predict how energy intake affects growth and composition and use this information profitably. The capacity for growing pigs to deposit lean meat is greater than their ability to consume energy. This means that they can be offered ad libitum access to high-energy diets without excessive fat or a drop in feed conversion efficiency. The more energy a pig consumes, the faster it will grow assuming the diet is adequately supplied with balanced protein.

In the slaughter pig, energy intake may exceed the requirement for maximum lean protein deposition, and the pig may begin to lay down proportionally more fat (relative to lean). This tends to be a greater problem in females and castrates than in entire males.

Eating behavior and appetite regulation

Pigs are very social animals and prefer to eat together. They use a lot of time to search for feed in their natural environment and generally, they are very motivated to eat and drink.

Until the weight of 50-60 kg, the feed intake is physically regulated. This means it is the capacity of the digestive tract that determines how much they eat. After 60 kg it is to a greater extent metabolically regulated, which means that it is the content of nutrients in the blood and filling of the gut regulating the feed intake. Pigs with a high genetic ability to metabolise the feed can eat more before the chemical regulation reduce the feed intake.

Gut capacity limits the amount of feed a growing pig can eat, so the voluntary energy intake of a pig weighing under 60kg depends on the diet’s energy concentration.

Understanding the digestion of the pig

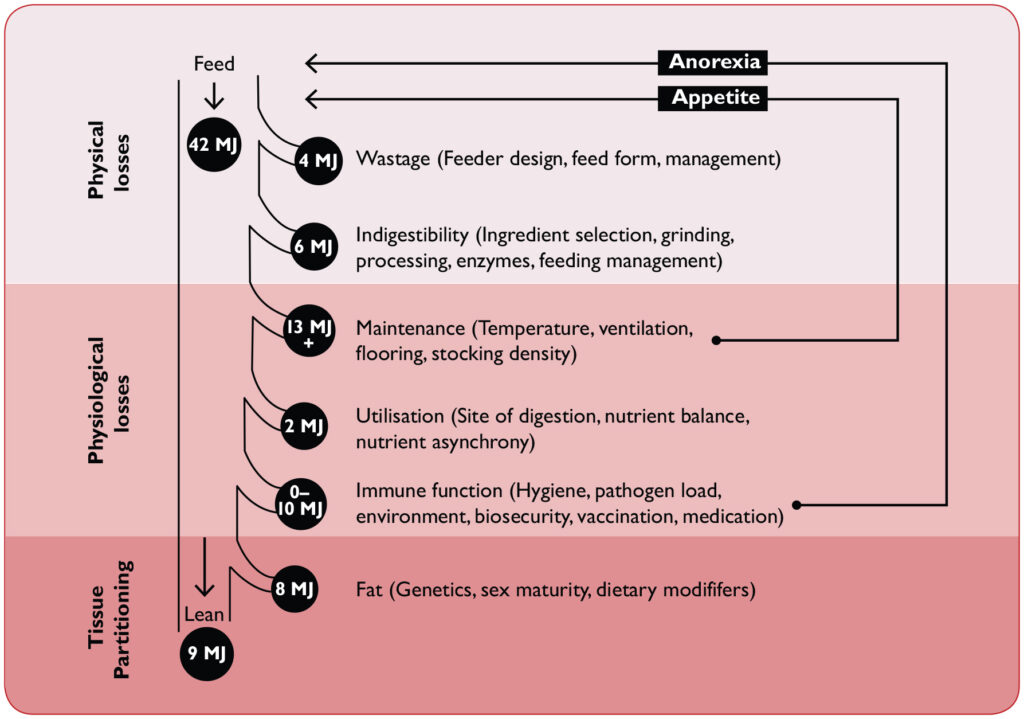

The key to efficient pork production is minimising the maintenance energy requirement of the pig so that they can maximise the use of the nutrients provided to them. However, as demonstrated in the table below, the majority of the nutrients are used by the pig to support their immune and metabolic demands. Outside of these requirements, nutrients can be used for fat and lean tissue growth.

The potential losses of energy occurring in a finisher pig consuming 42MJ of gross. Modified from ACE Livestock Consulting Pty Ltd, 2011.

The potential losses of energy occurring in a finisher pig consuming 42MJ of gross. Modified from ACE Livestock Consulting Pty Ltd, 2011.

The presence and ratio of all the necessary nutrients in the animal’s diet are very important. Nutrients are required to meet the basic animal needs, growth, metabolic and immune processes, and additional needs like reproductive abilities such as milk secretion in sows, foetal development, etc. It is normal to have some nutrient losses, but it is very important to minimize the same.

One way of nutrient and energy losses that an animal receives from a diet is to maintain a balance between good and harmful bacteria in the digestive tract, i.e. maintaining the normal gut microbiome of the animal. Currently, these losses have not been defined in sows, but for piglets, for example, there is evidence suggesting that up to 25% protein and up to 20% energy from a diet is required to maintain a normal balance between good and harmful bacteria in the gut. From this example, these nutrient and energy losses are not negligible and should be minimized.

By using organic acids in the diet of the sow, we can successfully control the number of harmful bacteria in the gut, which can significantly reduce these losses in nutrients and energy, giving a sow more opportunity to use them for other purposes.

High quality feed ingredients

DanBred animals come with an extraordinary genetic potential for reproductive performance. High-quality feed ingredients as well as monitoring the physical and nutrient standards of the ingredients whether purchased or homegrown are fundamental to the drive for consistent performance and in setting a prime starting point on the road to releasing the genetic potential for high lifetime productivity.

The energy and nutrient content of the ingredients used might differ from region to region so it is important to always have updated analyses of the ingredients going into the diet formulation. Careful attention to the type and quality of the ingredients going into the herd is an advantage when aiming for excellence.

This paper specifies the optimal nutrient requirements of DanBred sows and gilts and represents the nutritional level that the feed should reach regardless of ingredients and raw materials.

Adjusting raw feed ingredients

It is important to remember to adjust the raw feed ingredients gradually so that the pigs are weaned onto the new feed without changing the taste or consistency too severely. Changing the raw ingredients too much or too often will result in a decrease in feed intake at any stage of pig production, and will therefore result in a loss of production.

Frequent changes in diet, type of feed and feed ingredients in pigs can lead to various problems. This represents one big stress for these animals in general and it is mainly reflected in poorer appetite, bad digestion of nutrients and also an alteration of the gut microbiome in the animals themselves, which can cause health and production problems.

Organic acids (for example KDF, traded as FORMI®, ADDCON) in the diet of sows, piglets and slaughter pigs, contribute to a better appetite, stabilization and better digestion of nutrients when changing feed (better digestion of proteins and fats), as well as better utilization of minerals such as Calcium and Phosphorus. This is best seen in the weaning period when the piglets are changing from the sows’ milk to solid feed.

Health and production problems can be seen in the period of a feed change, caused by the increased development of pathogenic microflora (e.g. E. Coli). Organic acids with their bactericidal and bacteriostatic effect control the pathogen microflora in the intestine and improve the conditions for the commensal microflora of the animal, which also contributes to better digestion of new feeds, better health status and better production parameters.

Toxins

Mycotoxins are found in most raw feed materials worldwide and can have a direct and negative effect on reproductive performance in pigs. Mitigating these effects is therefore essential in high-performing pig units.

Mould and their Mycotoxins, yeast and endotoxins are naturally occurring contaminants and are among the most immune suppressive factors coming from the feed. The toxins are invisible, odourless and cannot be detected by smell or taste, but can impair animal health and immune status and will significantly reduce pig performance.

Mycotoxins are known anti-nutritional factors that affect reproduction. Over 400 different mycotoxins have been identified to date, with the most well-known being trichothecenes, zearalenone (ZEN), ochratoxins, aflatoxins, fumonisins and ergot alkaloids. Raw materials can be affected by more than one fungus, and each fungus can produce more than one mycotoxin- so there is a high chance that there is more than one mycotoxin in any feed ingredient.

In order to reduce the negative effects of toxins, it is important to test feed ingredients regularly. Toxin binders such as Mycofix® Plus (Biomin) can be added to the feed – DanBred recommends always consulting professionals before administering any additives.

Feed preservation with liquid organic acids products (Addcon XL 2.0) and organic acids salts (Addcon XF Superfine) can reduce the number of fungi, mould, yeasts, and pathogenic bacteria, and also lower the production of unwanted substances.

Physical properties of raw ingredients

Grain processing and subsequent particle size are one of the biggest factors affecting the efficiency of the pigs’ use of grains and diets. The correct adjustment of particle size can affect feed efficiency, however, if the particle size is too small the incidence of stomach ulcers can increase which greatly affects the performance of the sow.

There are three main ways in which grain is milled- roller, hammer and disc mills. Roller mills consist of two rollers that rotate towards each other, where the fineness to which the grain is processed can be adjusted by roller speed, shape and flutings. Hammer mills consist of many free-swinging strips of metal, acting as hammers, that are attached to a heavy-duty driveshaft turning at about 300rpm.

Screens with varying sizes of holes determine how long the grain is kept in contact with the hammer, and subsequently how fine the grain is milled. Disc mills operate on the grinding action of two discs or plates. The grain is ground between the discs which can be adjusted to the desired particle size. The disc mill has the capacity to pre-set grinding options to suit various classes of animals, e.g. a finer particle size for weaner pigs, and a coarser structure for slaughter or breeding animals.

Fibre

Dietary fibre, usually defined as the indigestible portion derived from plants, forms a key component of many pig diets.

The physiological properties of different fibres are related primarily to their solubility, viscosity, physical structure and water-holding capacity, rather than their constituent monomers.

Typically, dietary fibres have been categorised as either soluble fibres, which are fermented in the colon to produce gases and physiologically active by-products or insoluble fibres which are metabolically inert which can decrease the risk of constipation in sows- this, in turn, helps the sow when farrowing.

Thus, including fibre in the diet promotes normal physiological functions in the digestive tract. The inclusion of soluble non-starch polysaccharides (NSP) in the diet can stimulate the growth of commensal gut microbes, suggesting that fibre can have prebiotic effects in pigs due to interactions with the gut micro-environment and the gut-associated immune system. The inclusion of organic acids in the diet can stimulate the growth of commensal gut microbes. The increased fermentative capacity of sows makes diets high in dietary fibre more suitable for sows than growing pigs because these diets can be used to control energy intake and hunger at the same time and the sows can utilise energy from the fibre, whereas growing pigs could be limited in their growth when fed too much fibre.

Fibres in the feed have shown a positive effect on milk yield and piglet growth in the lactating sow. The fibre source is important if milk production should be improved.

Gut health

Optimal gut health is crucial for the optimal performance of the highly productive DanBred sow. Her longevity is dependent on optimal gut health in the early feeding of gilts, so that stomach ulcer development can be avoided. Gut health basically means a balance between good and bad microflora inside the intestine- if the balance favours bad microflora, this can lead to different health and production problems.

Some good examples of fibre content and their source are:

- Sugar beet pulp, lucerne pellets, oats, wheat bran, soybean hulls.

- Barley is preferred as the primary grain component.

- The structure of the grain component in the diet is required to be semi-rough ground as a minimum.

This feed structure can be achieved by following the sieve profile guide below:

| Composition | Below 1 mm | 1-2 mm | 2-3 mm |

|---|---|---|---|

| Distribution in particle size (grain part) | 50% | 35% | 15% |

The health of legs, feet and hooves

Toes that are slightly longer than normal will eventually impact the sows’ gait when walking. Sows experience heel overgrowth and erosion when there are cracks and overgrowth and/or erosion in the soft heel tissue or cracks in the claw wall.

Toes that are slightly longer than normal will eventually impact the sows’ gait when walking. Sows experience heel overgrowth and erosion when there are cracks and overgrowth and/or erosion in the soft heel tissue or cracks in the claw wall. Although of course, the environment in which they are housed in

plays a factor, many of these foot lesions are caused by a nutritional deficiency or imbalance and can be prevented by feeding the correct amount of the trace minerals- copper (Cu), zinc (Zn) and manganese (Mn) which are required by the sow.

- Manganese is essential for healthy joints, tendons and overall bone density.

- Zinc has a healing effect on wounds and contributes to the renewal of epithelial (skin) cells. A deficiency can cause cracks in the hoof.

- Copper is needed for strong connective tissue and white line health.

- Zinc and copper are also crucial in a sow’s diet for sole, heel and nail strength and elasticity.

Biotin is a water-soluble B Vitamin that helps the body convert into energy. It is also particularly important for the health of hair, skin and nails (together with Omega 3 fatty acids). Biotins function is similar to the mortar in a brick wall, while the brick quality is dependent on the micro minerals. Shortage of any of the components results in weak hoof nails.

Organic acid salts such as calcium propionate, calcium formate, and sodium benzoate (available as Addcon XF Superfine) can be an additional source of minerals for the pigs. Dissociated organic acids in the digestive tract of the animal together with minerals are creating a new compound (chelates), an easier form for animals to absorb and use minerals. An additional positive effect of using organic acids (KDF, traded as FORMI® by ADDCON) is a reduced ammonia level in the animal facilities, due to better digestion of proteins and utilisation of nitrogen.

The optimal supply of nutrients to the dermis supports the formation of strong and resistant claw horns. The addition of organically bound trace elements, such as Biomin® LocoMote, can help to improve the horn tissue.

Content of selected raw materials

To support the full production potential of DanBred pigs it is advised to stay within the recommended maximum percentage of each raw material mentioned in the table below. Diet formulation involves an accurate knowledge of the energy level and nutrient composition of feed ingredients. In addition, it is important to acknowledge that some feed ingredients contain elements that, if fed in excess, can have a negative impact on different production parameters.

| Raw material*, % | Gilts | Gestating sows | Lactating sows | Piglets from 3 weeks | Weaner from 5 weeks | Growers < 40 kg | Finishers > 40 kg |

|---|---|---|---|---|---|---|---|

| Soybeans, toasted | 15 | 20 | 20 | 10 | 20 | 15 | 15 |

| Soy protein concentrate (SPC) | 10 | 10 | 10 | 15 | 10 | 10 | 10 |

| Sunflower meal | 15 | 15 | 15 | 0 | 5 | 10 | 15 |

| Rapeseed cake and meal, DL | 15 | 12 | 12 | 5 | 5 | 10 | 15 |

| Rapeseeds | 4 | 12 | 12 | 0 | 4 | 4 | 4 |

| Palm kernel cake/expeller | 10 | 15 | 15 | 0 | 0 | 10 | 10 |

| Fishmeal |

0 | 5 | 5 | 12 | 12 | 2 | 0 |

| Barley |

90 | 90 | 90 | 70 | 70 | 70 | 70 |

| Wheat |

70 | 80 | 80 | 70 | 70 | 70 | 70 |

| Corn |

40 | 50 | 50 | 70 | 70 | 40 | 40 |

| Corn, gluten meal |

10 | 10 | 10 | 0 | 10 | 10 | 30 |

| Oats |

50 | 80 | 80 | 30 | 50 | 50 | 50 |

| Wheat bran | 20 | 20 | 20 | 10 | 20 | 20 | 20 |

| Palm oil | 6 | 6 | 6 | 7 | 7 | 5 | 3 |

| Soy or rapeseed oil | 6 | 6 | 6 | 7 | 7 | 5 | 2 |

| Fish oil | 0 | 0 | 0 | 7 | 7 | 0 | 0 |

| *The quality of raw ingredients is of high importance for ensuring the best performance at any production stage. | |||||||

The above table shows the advised maximum percentage of selected feed ingredients. An extended list can be found here.

Increased digestibility of phosphorus

Phytase is an enzyme that specifically acts on phytate, breaking it down to release phosphorus in a form easier available to the animal. This greatly reduces the need for supplemental inorganic phosphorus and improves the nutritional value of feedstuffs.

The below table explains the phytase units in selected phytase products at inclusion rates ranging from 60 to 400%.

| Inclusion | Natuphos (FTU) Phyzyme XP (FTU) Ronozyme HiPhos (FYT) Optiphos Plus (FTU) | Ronozyme NP (FYT) | Optiphos3 (OTU) | Optiphos3 (FTU) | Axtra Phy (FTU) | Quantum Blue (FTU) | Natuphos E (FTU) | Enzy8 Phostar (FTU) |

|---|---|---|---|---|---|---|---|---|

| 60% | 3001 | Below allowed inclusion rate |

1504 | 400 | 2506 | 2507 | 210 | 450 |

| 100% | 500 | 15002 | 250 | 670 | 3006 | 4007 | 350 | 750 |

| 150% | 750 | 1875 | 375 | 1005 | 450 | 600 | 525 | 1125 |

| 200% | 1000 | 2500 | 500 | 1340 | 600 | 800 | 700 | 1500 |

| 300% | 15005 | – | – | – | 900 | 1200 | 1050 | 2250 |

| 400% | 20005 | – | – | – | 1200 | 1600 | 1400 | 3000 |

| 1) Minimum inclusion allowed of Ronozyme HiPhos is 500 FYT. 2) 1250 FYT are required to obtain an effect corresponding to 100%, but the approved inclusion rate is 1500-3000 FYT per kg feed. 3) Optiphos is approved in the EU according to a different analysis method, the OTU. In practice, Optiphos can be verified with the standard method (FTU/FYT), and an EU test made at multiple laboratories revealed that 2.68 FTU equals 1.00 OTU. 4) Optiphos minimum inclusion in feed for weaned pigs: 250 OTU (100%). Max inclusion rate: 500 OTU. 5) Phyzyme is approved in inclusion rates up to 1000 FTU in feed for weaned pigs. 6) Axtraa Phy minimum inclusion: 250 FTU. 7) Quantum Blue minimum inclusion in feed for weaned pigs: 500 FTU. 8) Enzy Phostar is not pelleting-resistant and can only be used in meal-based feed. |

||||||||

Water supply and quality

Water is the single most important nutrient in any animal’s diet, however, its’ importance is often overlooked. About 75% of lean meat is water, and for all body functions to occur, water needs to be present in sufficient amounts for the processes to be carried out correctly- this includes the deposition of protein for muscle (lean meat).

Water consumption is closely linked to the feed intake in any production phase- if pigs cannot drink enough then they will eat less.

Water supply

The pigs’ need for water varies according to the time of year, the climate in the stable and their health status. If the pig is in bad health, the need for water can rise to double the normal. e.g. feeding grain with a high content of toxins. However, as a general rule, pigs consume 2-3 times more water than feed.

There should always be free access to clean, cool water and the animals’ need for water increases concurrently with the intake of feed. Gestating and lactating sows’ need for water is extraordinarily large due to foetal development and subsequent milk production.

One drinker can supply water to 10-15 pigs under normal conditions. The drinkers can be a nipple, bite or bowl, and at least two should be placed in the pen in case of blockage and also avoid aggression between pen mates over one drinker. They should be placed at least 60cm apart, and the height needs to be adjusted to suit the size and weight of the pigs. If a water trough is being used, it is recommended that a length of at least 300mm is provided for 20 slaughter pigs.

Water supply – Water cup and water nipple

Pigs must always have free access to fresh clean water. Although until 14 days of age, most of the piglets’ fluid needs are provided by the sows’ milk, it is still important that they learn to drink.

Check of water supply

It is important to check the flow rate every time a new group of animals enters the pen. The flow rate from the nipple must be between 0.5 – 0.8 litres per minute for piglets, 0.8 – 2 litres per minute for slaughter pigs and a minimum of 4 litres per minute for sows.

The daily water requirements for animals are dependent on their environment and climatic condition. In a tropic or subtropic climate (>30°C) the pigs have a greater water requirement than pigs kept in a temperate climate (15°C).

The following table indicates the average water requirements for pigs in each stage of production.

| Animal group | Litres per day |

|---|---|

| Suckling pigs | 1 – 2 |

| Piglets | 1 – 5 |

| Growers, 15 – 45 kg | 4 – 8 |

| Finishers, 45 – 100 kg | 6 – 10 |

| Gestating sows | 12 – 20 |

| Lactating sows | 35 – 50 |

| Boars | 8 – 10 |

For questions on requirements specific to your location please contact DanBred Technical Services Team for accurate information.

Water hygiene

It is extremely important to regularly disinfect the water system and remove any biofilm from the water pipes- as biofilm could be teeming with infectious bacteria.

- Empty and rinse the water system twice with an approved disinfectant and flush it at least once with clean water.

- Carry out the first rinse after washing the surface of the water nipples or drinkers

- Complete the second rinse the day before the animals arrive and not before.

- Let the cleaning product soak in for about 5 hours.

- Make sure the water system is rinsed with clean water at least once before the animal arrives.

Water quality

Like drinking water for human consumption, drinking water for pigs must be physically, chemically and microbiologically correct. It is important to know what the quality of water being offered to the pigs is as this impacts multiple factors of production including the pig’s water intake, the impact on the water delivery system (scale build-up can cause blockages), as well as the effect of delivery of nutrients and medications in the water.

Water for pigs should be of the same quality as water for human consumption. It is recommended to test water sources four times per year. The following table provides the basic recommendations for the normal quality composition of water.

| Standard | Good | Take action |

|---|---|---|

| pH | 5.5–8.5 | < 4 or > 9 |

| Ammonium (mg/l) | < 1.0 | > 2.0 |

| Nitrite (mg/l) | < 0.10 | > 1.00 |

| Nitrate (mg/l) | < 25 | > 100 |

| Chloride (mg/l) | < 250 | > 1,000 |

| Sodium (mg/l) | < 400 | > 800 |

| Sulphate (mg/l) | < 100 | > 250 |

| Iron (mg/l) | < 0.5 | > 10.0 |

| Manganese (mg/l) | < 1.0 | > 2.00 |

| Hardness (ppm) | < 60 | > 300 |

| Coliforms (cfu/ml) | < 100 | > 100 |

| Total bacterial count (cfu/ml) | < 100,000 | > 100,000 |

cfu = colony-forming units.

Nutrient tables for DanBred gilts

The energy density per kilo feed

The table below shows the recommended content of energy per kg feed in different weight stages when using restricted feeding.

| Energy. per kg feed | Gilts 30-110 kg | Gilts 30-65 kg | Gilts 65-110 kg | Gilts > 110 kg |

|---|---|---|---|---|

| MJ ME/kg feed | 12.8 | 13.0 | 12.8 | 12.5 |

| MJ NE/kg feed | 9.7 | 9.8 | 9.7 | 9.4 |

| Danish feed units (FU)sow/kg | 1.05 | 1.07 | 1.05 | 1.02 |

| The relation between MJ ME/MJ NE depends on the raw materials. | ||||

Protein and Amino acids

The table below shows the recommended content of Standardized Ileal Digestible (SID) protein and selected amino acids per kg feed when using restricted feeding.

| Amino acids. (digestible) | Gilts 30-110 kg | Gilts 30-65 kg | Gilts 65-110 kg | Gilts > 110 kg |

|---|---|---|---|---|

| SID protein. min. g/kg | 105 | 125 | 100 | 95 |

| Lysine. SID, g/kg | 6.3 | 8.2 | 5.3 | 4.2 |

| Total lysine, g/kg | 7.4 | 9.4 | 6.5 | 5.2 |

| Methionine. % of SID lysin | 31 | 31 | 31 | 31 |

| Methionine + Cysteine % of SID lysin | 58 | 58 | 65 | 65 |

| Threonine. % of SID lysin | 65 | 65 | 72 | 72 |

| Tryptophan. % of SID lysin | 20 | 20 | 20 | 20 |

| Isoleucine. % of SID lysin | 56 | 56 | 60 | 60 |

| Leucine. % of SID lysin | 108 | 108 | 102 | 102 |

| Histidine. % of SID lysin | 36 | 36 | 35 | 35 |

| Phenylalanine. % of SID lysin | 55 | 55 | 58 | 58 |

| Phenylalanine + tyrosine. % of SID lysin | 113 | 113 | 102 | 102 |

| Valine. % of SID lysin | 69 | 69 | 74 | 74 |

Macro and Micro minerals

The tables below show the recommended content of selected macro and micro minerals per kg feed when using restricted feeding.

| Macro minerals. g/kg | Gilts 30-110 kg | Gilts 30-65 kg | Gilts 65-110 kg | Gilts > 110 kg |

|---|---|---|---|---|

| Calcium without phytase | 7.7 | 8.5 | 7.4 | 7.1 |

| Calcium 60-100 % phytase | 7.2 | 8.0 | 6.9 | 6.9 |

| Calcium 150-250 % phytase | 6.9 | 7.7 | 6.6 | 6.3 |

| Calcium 300-400 % phytase | 6.7 | 7.5 | 6.4 | 6.1 |

| Total phosphorus. minimum (100% phytase) | 4.9 | 5.5 | 4.5 | 4.8 |

| Total phosphorus. minimum (200% phytase) | 4.5 | 5.2 | 4.1 | 4.3 |

| Total phosphorus. minimum (300% phytase) | 4.2 | 5.1 | 3.9 | 4.2 |

| Total phosphorus. minimum (400% phytase) | 4.1 | 5.0 | 3.8 | 4.1 |

| Digestible phosphorus | 2.6 | 3.2 | 2.4 | 2.1 |

| Sodium (Na)* | 2.0 | 2.0 | 2.0 | 2.0 |

| Magnesium (Mg)* | 0.6 | 1.1 | 0.6 | 0.6 |

| * Recommendations are based on the ideal situation, local legislation and regulations may apply for some elements. | ||||

| Micro minerals. mg/kg. Minimum * ** | Gilts 30-110 kg | Gilts 30-65 kg | Gilts 65-110 kg | Gilts > 110 kg |

|---|---|---|---|---|

| Iron (Fe ) | 85 | 85 | 85 | 82 |

| Copper (Cu) | 15 | 16 | 15 | 15 |

| Manganese (Mn) | 43 | 43 | 43 | 41 |

| Zinc (Zn) | 106 | 106 | 106 | 102 |

| Iodine (I) | 0.55 | 1.0 | 0.55 | 0.55 |

| Selenium (Se) | 0.25 | 0.25 | 0.25 | 0.25 |

| * Recommendations are based on the ideal situation, local legislation and regulations may apply for some elements. | ||||

| ** Highly prolific sows have a higher demand for nutrients, using a part of micro mineral supplements in organic form, could be beneficial to reach optimum production. | ||||

Vitamins and additives

The tables below show the recommended content of selected vitamins and additives per kg feed when using restricted feeding.

>* Recommendations are based on the ideal situation, local legislation and regulations may apply for some elements.

| Vitamins * | Gilts 30-110 kg | Gilts 30-65 kg | Gilts 65-110 kg | Gilts > 110 kg |

|---|---|---|---|---|

| A vitamin. 1000 IU/kg | 10 | 10 | 10 | 10 |

| D3 vitamin. 1000 IU/kg | 1.0 | 1.0 | 1.0 | 1.0 |

| E vitamin. mg/kg | 80** | 161*** | 80** | 80** |

| K3 vitamin. mg/kg | 4.0 | 4.0 | 4.0 | 4.0 |

| B1 vitamin. mg/kg | 2.1 | 2.2 | 2.1 | 2.1 |

| B2 vitamin. mg/kg | 2.1 | 5.4 | 5.2 | 5.2 |

| B6 vitamin. mg/kg | 3.2 | 3.3 | 3.2 | 3.2 |

| B12 vitamin. mg/kg | 0.03 | 0.03 | 0.03 | 0.03 |

| Biotin. mg/kg | 0.22 | 0.4 | 0.22 | 0.4 |

| Folic acid. mg/kg | 1.6 | 1.6 | 1.6 | 1.6 |

| Niacin. mg/kg | 21.4 | 22.0 | 21.4 | 21.0 |

| Pantothenic acid. mg/kg | 15.3 | 16.0 | 15.3 | 15.3 |

| * Recommendations are based on the ideal situation, local legislation and regulations may apply for some elements. ** This may vary dependent on i.e. dietary fat levels. *** This can be lowered to 80 mg/kg if the same diet is not used for lactating sows. |

||||

| Additional vitamins and additives *** | Gilts 30-110 kg | Gilts 30-65 kg | Gilts 65-110 kg | Gilts > 110 kg |

|---|---|---|---|---|

| C vitamin mg/kg | 200 | 200 | 200 | 200 |

| Betaine. mg/kg | – | – | – | 300 |

| DHA Omega-3. g/tons | Optional | Optional | Optional | Optional |

| Choline chloride. mg/kg | added | added | added | added |

| Antioxidant. mg/kg | added | added | added | added |

| Toxin binder. g/tons | added | added | added | added |

| *** Not demanded, recommended to reduce interfering factors and ensure feed quality. | ||||

Nutrient tables for DanBred sows

The energy density per kilo feed

The table below shows the recommended content of energy per kg feed in different production stages.

| Energy. per kg feed | Gestating sows | Lactating sows

Low energy density |

Lactating sows

High energy density |

|---|---|---|---|

| MJ ME/kg feed | 12.5 | 13.1 | 13.8 |

| MJ NE/kg feed | 9.4 | 9.9 | 10.5 |

| Danish feed units (FU)sow/kg | 1.02 | 1.07 | 1.013 |

| The relation between MJ ME/MJ NE depends on the raw materials. | |||

Digestible Protein and Amino acids

The table below shows the recommended content of Standardized Ileal Digestible (SID) protein and selected amino acids per kg feed in different production stages.

| Amino acids. (digestible) | Gestating sows | Lactating sows

Low energy density |

Lactating sows

High energy density |

|---|---|---|---|

| SID protein. min. g/kg | 95 | 125 | 134 |

| Lysine. SID g/kg | 4.2 | 8.2 | 8.7 |

| Methionine. % of SID lysin | 31 | 31 | 31 |

| Methionine + Cysteine % of SID lysin | 65 | 58 | 58 |

| Threonine. % of SID lysin | 72 | 65 | 65 |

| Tryptophan. % of SID lysin | 20 | 20 | 20 |

| Isoleucine. % of SID lysin | 60 | 56 | 56 |

| Leucine. % of SID lysin | 102 | 108 | 108 |

| Histidine. % of SID lysin | 35 | 36 | 36 |

| Phenylalanine. % of SID lysin | 58 | 55 | 55 |

| Phenylalanine + tyrosine. % of SID lysin | 102 | 113 | 113 |

| Valine. % of SID lysin | 74 | 69 | 69 |

Macro and Micro minerals

The tables below show the recommended content of selected macro and micro minerals per kg feed when in different production stages.

| Macro minerals. g/kg | Gestating sows | Lactating sows

Low energy density |

Lactating sows

High energy density |

|---|---|---|---|

| Calcium without phytase | 7.1 | 8.5 | 9.0 |

| Calcium 60-100 % phytase | 6.9 | 8.0 | 8.5 |

| Calcium 150-250 % phytase | 6.3 | 7.7 | 8.2 |

| Calcium 300-400 % phytase | 6.1 | 7.5 | 8.0 |

| Total phosphorus. minimum (100% phytase) | 4.8 | 5.5 | 5.8 |

| Total phosphorus. minimum (200% phytase) | 4.3 | 5.2 | 5.5 |

| Total phosphorus. minimum (300% phytase) | 4.2 | 5.1 | 5.4 |

| Total phosphorus. minimum (400% phytase) | 4.1 | 5.0 | 5.3 |

| Digestible phosphorus | 2.1 | 3.2 | 3.4 |

| Sodium (Na)* | 2.0 | 2.0 | 2.0 |

| Magnesium (Mg)* | 0.6 | 1.1 | 1.2 |

| * Recommendations are based on the ideal situation, local legislation and regulations may apply for some elements. | |||

| Micro minerals. mg/kg. Minimum * ** | Gestating sows | Lactating sows

Low energy density |

Lactating sows

High energy density |

|---|---|---|---|

| Iron (Fe ) | 82 | 85 | 90 |

| Copper (Cu) | 15 | 16 | 17 |

| Manganese (Mn) | 41 | 43 | 45 |

| Zinc (Zn) | 102 | 107 | 113 |

| Iodine (I) | 0.55 | 1.0 | 1.1 |

| Selenium (Se) | 0.25 | 0.25 | 0.25 |

| * Recommendations are based on the ideal situation, local legislation and regulations may apply for some elements. | |||

| ** Highly prolific sows have a higher demand for nutrients, using a part of micro mineral supplements in organic form, could be beneficial to reach optimum production. | |||

Vitamins and additives

The tables below show the recommended content of selected vitamins and additives per kg feed when in different production stages.

| Vitamins * | Gestating sows | Lactating sows

Low energy density |

Lactating sows

High energy density |

|---|---|---|---|

| A vitamin. 1000 IU/kg | 10 | 10 | 10 |

| D3 vitamin. 1000 IU/kg | 1.0 | 1.0 | 1.0 |

| E vitamin. mg/kg | 80 | 161 | 170 |

| K3 vitamin. mg/kg | 4.0 | 4.0 | 4.0 |

| B1 vitamin. mg/kg | 2.1 | 2.2 | 2.3 |

| B2 vitamin. mg/kg | 5.2 | 5.4 | 5.7 |

| B6 vitamin. mg/kg | 3.2 | 3.3 | 3.4 |

| B12 vitamin. mg/kg | 0.03 | 0.03 | 0.03 |

| Biotin. mg/kg | 0.4 | 0.4 | 0.4 |

| Folic acid. mg/kg | 1.6 | 1.6 | 1.7 |

| Niacin. mg/kg | 21.0 | 22.0 | 23.0 |

| Pantothenic acid. mg/kg | 15.3 | 16.0 | 17.0 |

| * Recommendations are based on the ideal situation, local legislation and regulations may apply for some elements. | |||

| Additional vitamins and additives *** | Gestating sows | Lactating sows

Low energy density |

Lactating sows

High energy density |

|---|---|---|---|

| C vitamin mg/kg | Optional | Optional | Optional |

| Betaine. mg/kg | Optional | Optional | Added |

| DHA Omega-3. g/tons | Optional | Optional | Optional |

| Choline chloride. mg/kg | Optional | Optional | Optional |

| Antioxidant. mg/kg | Added | Added | Added |

| Toxin binder. g/tons | Suggested | Suggested | Suggested |

| *** Not demanded, recommended to reduce interfering factors and ensure feed quality. | |||

Nutrient tables for DanBred Piglets and Weaners

Please note that the general nutritional recommendations for piglets do not include a safety margin, as they are determined as the economical optimum levels in diets containing conventional ingredients at normal price relations. Consequently, it is possible to improve performance by increasing amino acids and protein, but this will not be profitable as the increase in price exceeds performance improvements. Furthermore, a protein increase will increase the risk of diarrhoea outbreaks.

In the case of diarrhoea, the minimum standards can be selected, otherwise use the typical or maximum standards.

Calcium levels in feed for small piglets are lower than normal, because a high calcium concentration from calcium carbonate increases the risk of diarrhoea, and consequently calcium levels are a compromise between the risk of diarrhoea and maximum bone mineralization.

The energy density per kilo feed

The table below shows the recommended content of energy per kg feed in different weight stages.

| Energy. per kg feed | Piglets 6-9 kg | Piglets 9-15 kg | Piglets 15-30 kg |

|---|---|---|---|

| MJ ME/kg feed | 14.5 | 14.0 | 13.6 |

| MJ NE/kg feed | 10.7 | 10.3 | 10.0 |

| Danish feed units (FU)pig/kg | 1.20 | 1.16 | 1.12 |

| The relation between MJ ME/MJ NE depends on the raw materials. | |||

Protein and Amino acids

The table below shows the recommended content of Standardized Ileal Digestible (SID) protein and selected amino acids per kg feed when using restricted feeding.

| Protein | Piglets 6-9 kg | Piglets 9-15 kg | Piglets 15-30 kg |

|---|---|---|---|

| SID Protein. Min. g/kg | 158 | 162 | 160 |

| SID Protein. Avg. g/kg | 162 | 166 | 164 |

| SID Protein. Max. g/kg | 168 | 172 | 169 |

| Crude Protein. Min. % | 17.9 | 17.1 | 18.4 |

| Crude Protein.1 Avg. % | 18.4 | 18.8 | 18.8 |

| Crude Protein. Max. % | 19.1 | 19.5 | 29.4 |

| 1) In zinc-free diets crude protein can be lowered with -0,5 -1,0 % | |||

| Amino acids. (digestible) | Piglets 6-9 kg | Piglets 9-15 kg | Piglets 15-30 kg | % of lysine* |

|---|---|---|---|---|

| Lysine. SID, g/kg | 13.2 | 12.8 | 12.9 | 100 |

| Methionine SID, g/kg | 4.2 | 4.1 | 4.1 | 32 |

| Methionine + Cysteine SID, g/kg | 7.1 | 6.8 | 6.9 | 542 |

| Threonine SID, g/kg | 8.2 | 7.9 | 7.9 | 62 |

| Tryptophan SID, g/kg | 3.0 | 2.9 | 2.7 | 21-23 |

| Isoleucine SID, g/kg | 6.0 | 5.8 | 6.2 | 49-512 |

| Leucine SID, g/kg | 11.4 | 11.0 | 11.6 | 90-952 |

| Histidine SID, g/kg | 3.6 | 3.5 | 3.7 | 29-312 |

| Phenylalanine SID, g/kg | 7.1 | 6.8 | 6.9 | 542 |

| Phenylal.+tyrosine SID, g/kg | 12.6 | 12.2 | 12.2 | 1002 |

| Valine SID, g/kg | 8.3 | 8.0 | 8.2 | 63-65 |

| *) The amino acid levels are valid for the energy level shown above. At a higher energy level, more amino acid is required. 2) Depending on the choice of raw materials. |

||||

Macro and Micro minerals

The tables below show the recommended content of selected macro and micro minerals per kg feed.

| Macro minerals. g/kg | Piglets 6-9 kg | Piglets 9-15 kg | Piglets 15-30 kg |

|---|---|---|---|

| Calcium without phytase | 8.4 | 9.3 | 9.6 |

| Calcium 60-100% phytase | 7.8 | 8.7 | 9.0 |

| Calcium 150-250% phytase | 7.4 | 8.4 | 8.7 |

| Calcium 300-400% phytase | 7.2 | 8.1 | 8.5 |

| Digestible phosphorus | 4.0 | 3.7 | 3.7 |

| Sodium (Na)* | 3.0 | 2.4 | 2.1 |

| Magnesium (Mg)* | 1.1 | 1.1 | 1.0 |

| Chloride (Cl)* | 4.8 | 4.1 | 3.6 |

| Potassium (K)* | 2.5 | 2.9 | 2.8 |

| * Recommendations are based on the ideal situation, local legislation and regulations may apply for some elements. | |||

Guiding minimum content of total phosphorus in complete piglet diets with phytase. For general recommendations on phytase see this section

| Phosphorus | Piglets 9-30 kg |

|---|---|

| Digestible phosphorus. Avg. | 3.7 |

| Total phosphorus. minimum (100% phytase) | 6.3 |

| Total phosphorus. minimum (200% phytase) | 5.9 |

| Total phosphorus. minimum (300% phytase) | 5.7 |

| Total phosphorus. minimum (400% phytase) | 5.6 |

| Micro minerals. mg/kg. Minimum * | Piglets 6-9 kg | Piglets 9-15 kg | Piglets 15-30 kg |

|---|---|---|---|

| Iron (Fe ) | 180 | 174 | 170 |

| Copper (Cu) | 7 | 7 | 7 |

| Manganese (Mn) | 48 | 46 | 45 |

| Zinc (Zn) | 120 | 116 | 113 |

| Iodine (I) | 0.4 | 0.4 | 0.3 |

| Selenium (Se) | 0.4 | 0.4 | 0.4 |

| * Recommendations are based on the ideal situation, local legislation and regulations may apply for some elements. | |||

Vitamins and additives

The tables below show the recommended content of selected vitamins and additives per kg feed when using restricted feeding.

| Vitamins * | Piglets 6-9 kg | Piglets 9-15 kg | Piglets 15-30 kg |

|---|---|---|---|

| A vitamin. IU/kg | 9600 | 5800 | 5660 |

| D3 vitamin. IU/kg | 960 | 580 | 565 |

| E vitamin. mg/kg | 168 | 162 | 68 |

| – equal to Vit E (dl.- alpha-tocopherol), mg | 156 | 151 | 61 |

| – equal to Vit E (all-rac acetate), mg | 168 | 162 | 68 |

| – equal to Vit E (RRR), mg | 113 | 109 | 45 |

| – equal to Vit E (RRR acetate), mg | 124 | 119 | 50 |

| K3 vitamin. mg/kg | 2 | 2 | 2 |

| B1 vitamin. mg/kg | 2 | 2 | 2 |

| B2 vitamin. mg/kg | 5 | 5 | 5 |

| B6 vitamin. mg/kg | 4 | 3 | 3 |

| B12 vitamin. mg/kg | 24 | 23 | 23 |

| Biotin. mg/kg | 0.24 | 0.23 | 0.23 |

| Folic acid. mg/kg | 0 | 0 | 0 |

| Niacin. mg/kg | 24 | 23 | 23 |

| Pantothenic acid. mg/kg | 12 | 12 | 11 |

| * Recommendations are based on the ideal situation, local legislation and regulations may apply for some elements. | |||

Raw materials and their usability in pre-starter feed

| Raw material | Nutrient | Comment | Treatment | Usability |

|---|---|---|---|---|

| Wheat | Starch/energy | Low in complex carbohydrates/fibre | Cleaned | +++ |

| Barley | Starch/energy | Rich in complex carbohydrates (beta-glucans) fibre | Cleaned | ++ |

| Corn | Starch/energy | Resistant starch is not digested, but fermented. Resistant starch can be available using extrusion. Low in complex carbohydrates/fibre. |

Cleaned Extruded |

+++ |

| Rice | Starch /energy | Low in complex carbohydrates/fibre | Cleaned | +++ |

| soybean meal (SBM) | Protein and complex carbohydrates. | High in ANF: TIA, beta conglycinin, and oligosaccharides. | Toasted (Extruded) |

+ |

| Full Fat Soy (FFS) | Protein, fat, and complex carbohydrates | Very high in ANF: TIA, beta conglycinin, and oligosaccharides. Low protein SID. | Extruded or Micronized |

– |

| HP 300, Soy Protein Concentrate (SPC) | Protein and complex carbohydrates. | Low in ANF: TIA, beta conglycinin, and oligosaccharides. High protein digestibility; WHC; prebiotic effect |

Enzyme treated | +++ |

| Soy Protein Concentrates, (SPC) | Protein and inert carbohydrates | Low in ANF: TIA, beta conglycinin, and oligosaccharides. Low protein digestibility and WHC |

Water/alcohol extracted | ++ |

| SPC, Fermented | Protein and complex carbohydrates | Low in ANF: TIA, beta conglycinin, and oligosaccharides. Low protein digestibility and WHC |

Lactobacillus fermented | + |

| Fish Meal | Protein | Large variations in quality and digestibility. High in NPN, Non-Protein-Nitrogen. | Dried | ++ |

| Potato Protein Concentrate | Protein | High in ANF: TIA and Solanine+Cabomine | Ultra-filtration | ++ |

| Whey Powder, sweet | Lactose and protein | Used for supplying lactose | – | +++ |

| Fat/oil | Energy | Used for supplying energy | – | +++ |

Advised maximum percentage of selected feed ingredients for piglets 2 – 15 kg

| Raw material | Piglets 2-6 kg | Piglets 6-9 kg | Piglets 9-15 kg |

|---|---|---|---|

| Wheat | 70 | 70 | 70 |

| Barley | 70 | 70 | 70 |

| Corn | 70 | 70 | 40 |

| Rice | 50 | 50 | 50 |

| Soybean meal (SBM) | – | – | 10 |

| Full-Fat Soy (FFS) | – | – | – |

| HP 300 | 18 | 18 | 10 |

| Soy Protein Concentrates (SPC) | 15 | 10 | 10 |

| Fish Meal | 12 | 6 | 2 |

| Potato protein concentrate | 3 | 5 | 5 |

| Whey Powder, 70% lactose | 15-25 | 10-15 | 6-25 |

| Fat/Oil | +++ | ++ | ++ |

| Enzymes | Glu, Xyl, Phyt | Glu, Xyl, Phyt | Phyt |

| Organic Acids | 1% | 1% | 1% |

| Dietary Fibers | +++ | ++ | ++ |

| Calcium | low | low | medium |

| CaCO3 | <0.1 | <0.1 | <0.5 |

The above table shows the advised maximum percentage of selected feed ingredients. An extended list can be found here.

Nutrient tables for DanBred growers

The optimal feeding of growers in their different weight intervals depends on the feed conversion in the entire finisher period of 30-115 kg. DanBred has for growers chosen to simplify the nutritional tables to fit an average feed conversion between 32.6 MJ ME/23.3 MJ NE/2.6 FU per kg gain to 34.4 MJ ME/24.7 MJ NE/2.75 FU per kg gain.

To utilise the full potential of genetics it can be an advantage to optimise the feed composition according to the actual feed conversion rate achieved in the different weight stages and also ensure maximised protein utilisation at a balanced protein level to secure the gut health among the pigs.

Some will argue that it is possible to improve performance by increasing amino acids and protein levels, this should though never be done without calculating if the increase in feed price is balanced according to the performance improvements. Furthermore, a high-protein diet will increase the risk of diarrhoea outbreaks.

If you need an analysis of your grower production the technical team within DanBred is always available to help clarify production capacity and recommend a solution that can optimise your outcome.

The energy density per kilo feed

The table below shows the recommended content of energy per kg feed in different weight stages.

| Energy. per kg feed | 20-45 kg | 30-45 kg | 30-60 kg | 30-75 kg | 30-100 kg |

|---|---|---|---|---|---|

| MJ ME/kg feed | 13.8 | 13.6 | 13.5 | 13.2 | 13.4 |

| MJ NE/kg feed | 9.8 | 9.7 | 9.6 | 9.4 | 9.6 |

| Danish feed units (FU)pig/kg | 1.10 | 1.09 | 1.08 | 1.06 | 1.07 |

| The relation between MJ ME/MJ NE depends on the raw materials. | |||||

Digestible Protein and Amino acids

The table below shows the recommended content of Standardised Ileal Digestible (SID) protein and selected amino acids per kg feed in different weight stages at average feed conversion.

| Amino Acids, g/kg | 20-45 kg | 30-45 kg | 30-60 kg | 30-75 kg | % of Lysine* |

|---|---|---|---|---|---|

| SID protein. min. g/kg | 145.2 | 140.6 | 138.2 | 132.5 | – |

| SID Lysine | 10.7 | 10.0 | 9.6 | 9.1 | 100 |

| SID Methionine | 3.3 | 3.1 | 2.9 | 2.8 | 30-31 |

| SID Methionine + Cysteine | 5.9 | 5.7 | 5.5 | 5.3 | 55-58 |

| SID Threonine | 6.7 | 6.4 | 6.2 | 5.9 | 63-65,5 |

| SID Tryptophan | 2.1 | 2.0 | 1.9 | 1.8 | 20 |

| SID Isoleucine | 5.4 | 5.1 | 5.0 | 4.8 | 50-53 |

| SID Leucine | 10.1 | 9.6 | 9.6 | 9.1 | 94-100 |

| SID Histidine | 3.7 | 3.1 | 3.0 | 2.9 | 30-32 |

| SID Phenylalanine | 5.7 | 5.5 | 5.2 | 4.9 | 54 |

| SID Phenylalanine + Tyrosine | 10.7 | 10.8 | 9.6 | 9.1 | 100 |

| SID Valine | 6.8 | 6.5 | 6.2 | 5.8 | 64 |

| * The amino acid levels are valid for the energy level mentioned. At a higher energy level, more amino acid is required. | |||||

Macro and Micro minerals

The tables below show the recommended content of selected macro and micro minerals per kg feed in different weight stages at average feed conversion.

| Macro minerals. g/kg | 20-45 kg | 30-45 kg | 30-60 kg | 30-75 kg |

|---|---|---|---|---|

| Calcium without phytase | 8.6 | 8.3 | 8.0 | 7.6 |

| Calcium 60-100% phytase | 8.0 | 7.7 | 7.5 | 7.1 |

| Calcium 150-250% phytase | 7.7 | 7.4 | 7.1 | 6.8 |

| Calcium 300-400% phytase | 7.5 | 7.2 | 6.9 | 6.6 |

| Digestible phosphorus | 3.0 | 2.8 | 2.7 | 2.4 |

| Sodium (Na)* | 1.9 | 1.9 | 1.7 | 1.7 |

| Magnesium (Mg)* | 0.9 | 0.9 | 0.8 | 0.7 |

| Chloride (Cl)* | 3.1 | 3.1 | 2.9 | 2.9 |

| Potassium (K)* | 2.8 | 2.7 | 2.7 | 2.7 |

| * Recommendations are based on the ideal situation, local legislation and regulations may apply for some elements. | ||||

| Micro minerals. mg/kg. Minimum * | 20-45 kg | 30-45 kg | 30-60 kg | 30-75 kg |

|---|---|---|---|---|

| Iron (Fe ) | 90 | 90 | 90 | 90 |

| Copper (Cu) | 15 | 15 | 15 | 15 |

| Manganese (Mn) | 45 | 45 | 45 | 45 |

| Zinc (Zn) | 110 | 110 | 110 | 110 |

| Iodine (I) | 0.33 | 0.33 | 0.33 | 0.33 |

| Selenium (Se) | 0.25 | 0.25 | 0.25 | 0.25 |

| * Recommendations are based on the ideal situation, local legislation and regulations may apply for some elements. | ||||

Vitamins and additives

The tables below show the recommended content of selected macro and micro minerals per kg feed in different weight stages at average feed conversion.

| Vitamins * | 20-45 kg | 30-45 kg | 30-60 kg | 30-75 kg |

|---|---|---|---|---|

| A vitamin. IU/kg | 4880 | 4880 | 4880 | 4880 |

| D3 vitamin. IU/kg | 440 | 440 | 440 | 440 |

| E vitamin. mg/kg | 44 | 44 | 44 | 44 |

| – equal to Vit E (dl.- alpha-tocopherol), mg | 39 | 39 | 39 | 39 |

| – equal to Vit E (all-rac acetate), mg | 44 | 44 | 44 | 44 |

| – equal to Vit E (RRR), mg | 29 | 29 | 29 | 29 |

| – equal to Vit E (RRR acetate), mg | 31 | 31 | 31 | 31 |

| K3 vitamin. mg/kg | 2 | 2 | 2 | 2 |

| B1 vitamin. mg/kg | 2 | 2 | 2 | 2 |

| B2 vitamin. mg/kg | 2 | 2 | 2 | 2 |

| B6 vitamin. mg/kg | 3 | 3 | 3 | 3 |

| B12 vitamin. mg/kg | 21 | 21 | 21 | 21 |

| Biotin. mg/kg | 0.1 | 0.1 | 0.1 | 0.1 |

| Folic acid. mg/kg | 0 | 0 | 0 | 0 |

| Niacin. mg/kg | 21 | 21 | 21 | 21 |

| Pantothenic acid. mg/kg | 11 | 11 | 11 | 11 |

| * Recommendations are based on the ideal situation, local legislation and regulations may apply for some elements. | ||||

Nutrient tables for DanBred finishers

The optimal feeding of finishers in their different weight intervals depends on the feed conversion in the entire finisher period 30-115 kg. DanBred has for finishers chosen to simplify the nutritional tables to fit an average feed conversion between 32.6 MJ ME/23.3 MJ NE/2.6 FU per kg gain to 34.4 MJ ME/24.7 MJ NE/2.75 FU per kg gain.

To utilise the full potential of genetics it can be an advantage to optimise the feed composition according to the actual feed conversion rate achieved in the different weight stages. Some will argue that it is possible to improve performance by increasing amino acids and protein levels, this should though never be done without calculating if the increase in feed price is balanced according to the performance improvements.

If you need an analysis of your grower production the technical team within DanBred is always available to help clarify production capacity and recommend a solution that can optimise your outcome

The energy density per kilo feed

The table below shows the recommended content of energy per kg feed in different weight stages.

| Energy. per kg feed | 30 -100 kg | 30 -75 kg | 45 -75 kg | 60 -115 kg | 75 -115 kg |

|---|---|---|---|---|---|

| MJ ME/kg feed | 13.4 | 13.2 | 13.2 | 13.1 | 13.1 |

| MJ NE/kg feed | 9.6 | 9.4 | 9.4 | 9.3 | 9.3 |

| Danish feed units (FU)pig/kg | 1.07 | 1.06 | 1.06 | 1.05 | 1.05 |

| The relation between MJ ME/MJ NE depends on the raw materials. | |||||

Digestible Protein and Amino acids

The table below shows the recommended content of Standardized Ileal Digestible (SID) protein and selected amino acids per kg feed in different weight stages at average feed conversion.

| Amino Acids, g/kg | 30 -100 kg | 30 -75 kg | 45 -75 kg | 60 -115 kg | 75 -115 kg | % of Lysine* |

|---|---|---|---|---|---|---|

| SID protein. min. g/kg | 128.4 | 133 | 128.4 | 118 | 113.4 | – |

| SID Lysine | 8.8 | 9.1 | 8.8 | 8.0 | 7.7 | 100 |

| SID Methionine | 2.7 | 2.7 | 2.7 | 2.4 | 2.3 | 30 |

| SID Methionine + Cysteine | 5.0 | 5.3 | 5.0 | 4.4 | 4.5 | 58-61 |

| SID Threonine | 5.8 | 5.9 | 5.8 | 4.9 | 5.1 | 65.5-67 |

| SID Tryptophan | 1.8 | 1.8 | 1.8 | 1.5 | 1.5 | 20 |

| SID Isoleucine | 4.6 | 4.9 | 4.6 | 4.1 | 4.1 | 53 |

| SID Leucine | 8.8 | 9.1 | 8.8 | 7.7 | 7.7 | 100 |

| SID Histidine | 2.8 | 3.0 | 2.8 | 2.4 | 2.4 | 32 |

| SID Phenylalanine | 4.7 | 4.9 | 4.7 | 4.1 | 4.1 | 54 |

| SID Phenylalanine + Tyrosine | 8.8 | 9.1 | 8.8 | 7.7 | 7.7 | 100 |

| SID Valine | 5.6 | 5.8 | 5.6 | 4.9 | 4.9 | 64 |

| * The amino acid levels are valid for the energy level mentioned. At a higher energy level, more amino acid is required. |

||||||

Macro and Micro minerals

The tables below show the recommended content of selected macro and micro minerals per kg feed in different weight stages at average feed conversion.

| Macro minerals. g/kg | 30 -100 kg | 30 -75 kg | 45 -75 kg | 60 -115 kg | 75 -115 kg |

|---|---|---|---|---|---|

| Calcium without phytase | 7.5 | 7.6 | 7.4 | 7.1 | 6.9 |

| Calcium 60-100% phytase | 7.1 | 7.0 | 6.9 | 6.6 | 6.4 |

| Calcium 150-250% phytase | 6.6 | 6.8 | 6.6 | 6.3 | 6.1 |

| Calcium 300-400% phytase | 6.6 | 6.4 | 6.2 | 6.0 | 5.9 |

| Digestible phosphorus | 2.5 | 2.5 | 2.4 | 2.2 | 2.1 |

| Sodium (Na)* | 1.6 | 1.7 | 1.6 | 1.5 | 1.4 |

| Magnesium (Mg)* | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 |

| Chloride (Cl)* | 2.7 | 2.9 | 2.7 | 2.4 | 2.3 |

| Potassium (K)* | 2.7 | 2.7 | 2.7 | 2.6 | 2.6 |

| * Recommendations are based on the ideal situation, local legislation and regulations may apply for some elements. | |||||

| Micro minerals. mg/kg. Minimum * | 30 -100 kg | 30 -75 kg | 45 -75 kg | 60 -115 kg | 75 -115 kg |

|---|---|---|---|---|---|

| Iron (Fe ) | 90 | 90 | 90 | 90 | 90 |

| Copper (Cu) | 15 | 15 | 15 | 15 | 15 |

| Manganese (Mn) | 45 | 45 | 45 | 45 | 45 |

| Zinc (Zn) | 110 | 110 | 110 | 110 | 110 |

| Iodine (I) | 0.32 | 0.32 | 0.32 | 0.32 | 0.32 |

| Selenium (Se) | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 |

| * Recommendations are based on the ideal situation, local legislation and regulations may apply for some elements. | |||||

Vitamins and additives

The tables below show the recommended content of selected macro and micro minerals per kg feed in different weight stages at average feed conversion.

| Vitamins * | 30 -100 kg | 30 -75 kg | 45 -75 kg | 60 -115 kg | 75 -115 kg |

|---|---|---|---|---|---|

| A vitamin. IU/kg | 4880 | 4880 | 4880 | 4880 | 4880 |

| D3 vitamin. IU/kg | 440 | 440 | 440 | 440 | 440 |

| E vitamin. mg/kg | 43 | 43 | 43 | 43 | 43 |

| – equal to Vit E (dl.- alpha-tocopherol), mg | 39 | 39 | 39 | 39 | 39 |

| – equal to Vit E (all-rac acetate), mg | 43 | 43 | 43 | 43 | 43 |

| – equal to Vit E (RRR), mg | 29 | 29 | 29 | 29 | 29 |

| – equal to Vit E (RRR acetate), mg | 31 | 31 | 31 | 31 | 31 |

| K3 vitamin. mg/kg | 2 | 2 | 2 | 2 | 2 |

| B1 vitamin. mg/kg | 2 | 2 | 2 | 2 | 2 |

| B2 vitamin. mg/kg | 2 | 2 | 2 | 2 | 2 |

| B6 vitamin. mg/kg | 3 | 3 | 3 | 3 | 3 |

| B12 vitamin. mg/kg | 21 | 21 | 21 | 21 | 21 |

| Biotin. mg/kg | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| Folic acid. mg/kg | 0 | 0 | 0 | 0 | 0 |

| Niacin. mg/kg | 21 | 21 | 21 | 21 | 21 |

| Pantothenic acid. mg/kg | 11 | 11 | 11 | 11 | 11 |

| * Recommendations are based on the ideal situation, local legislation and regulations may apply for some elements. | |||||